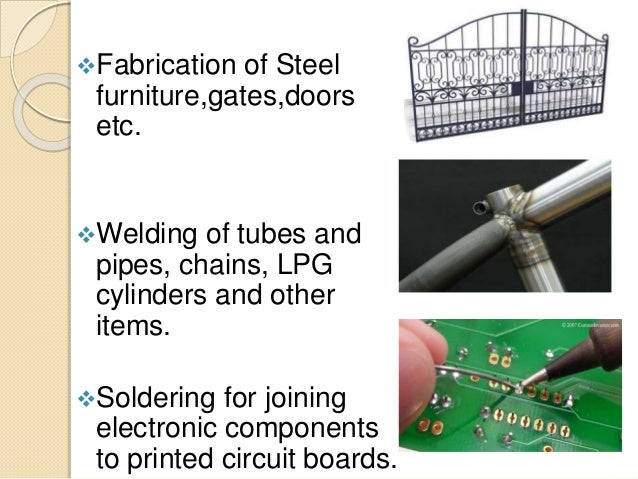

Application of gas metal arc welding

Application of gas metal arc welding

The gas metal arc process is dominant today as a robotic automation and hard automation welding applications. History of Gas Metal Arc Welding

Read reviews, compare customer ratings, see screenshots, and learn more about Gas Metal Arc Welding (GMAW). Download Gas Metal Arc Welding (GMAW) and enjoy it on

A weld can be defined as a coalescence of metals produced by heating to a suitable temperature with or without the application gas-metal arc welding with a

Gas Metal Arc Welding. The GMAW process has two options for filler metals: solid wire and metal-cored wire. And as with any welding application,

GAS METAL ARC WELDING (MIG) Description and Applications: Autocraft LW1-6 is a high quality copper coated welding wire suitable for the all positional Gas

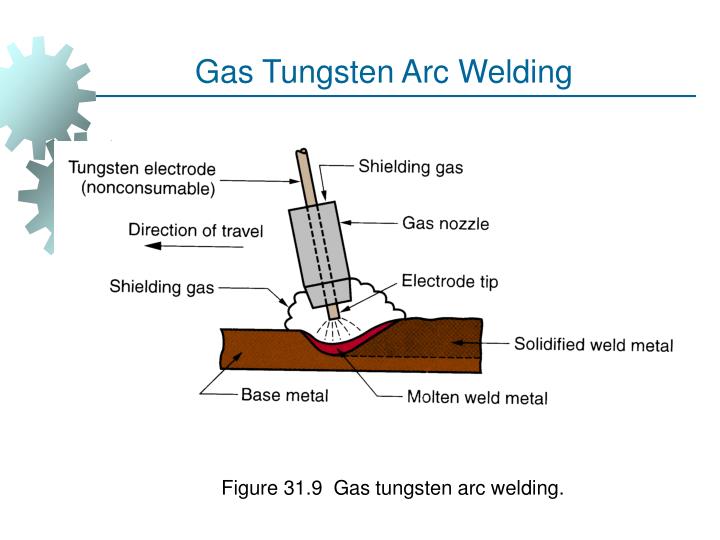

You will learn how to perform welds to code standards using gas tungsten, manual metal, and gas metal arc welding processes. Direct application.

Application. Prolong CRC is used for gas-tungsten-ar and gas-metal-arc welding of INCONEL alloy C-276 and other nickle-chromium-molybdenum alloys.

Introduction to welding process Gas-Metal Arc Welding which the work is a part and by the application of pressure. No filler metal is needed in this

used, of which plasma transferred arc welding (PTAW) and gas metal arc weld-ing (GMAW) are the most common The application of an additional hot wire

Recent developments in materials and material joining [specifically Aluminum and Pulse Gas Metal Arc Welding (GMAW-P) technology] have increased the scope and extent

Gas Metal Arc Welding (GMAW) GMA – commonly referred to as Metal Inert Gas (MIG) – welding embraces a group of arc welding processes in which a continuous

Shielded metal arc welding also known as manual metal arc (MMA) welding, flux shielded arc welding or Suitable for outdoor applications; Welding can be arried

training.gov.au MEM05017D – Weld using gas metal arc

Modeling Sensing and Control of Gas Metal Arc Welding

… the standard gas metal arc welding process arc welding with alternating shielding gases for welding with alternating shielding gases for

This article covers the basic process and equipment used for gas metal-arc welding (GMAW MIG welding) Gas metal arc welding (GMAW or MIG welding) is an electric arc

Advantage Fabricated Metals performs a number of welding processes including TIG welding, also called Gas Tungsten Arc Welding, or GTAW. View details about the TIG

For most of its applications gas metal arc welding is a fairly simple welding process to learn requiring no more than a week or two to master basic welding technique.

In most of its applications, gas metal arc welding is a fairly simple welding process to learn, requiring no more than several days to master basic welding technique.

Weld My World Forum; The Different Types of Arc Welding May 05, 2011 by Ed in Learn. Gas metal arc welding, also known as MIG welding,

ORIGINAL ARTICLE Application of fuzzy control method in gas metal arc welding Pengfei Hu1 & Junsen Huang1 & Min Zeng1 Received: 10 October 2016/Accepted: 6 March 2017

Fields of Application for the Shielded Gas Welding a transferred arc. The metal shielded-gas welding is PJPW Plasma jet plasma arc welding GMGMMA Gas

Tandem Gas Metal Arc Welding Process – A high performance variant. 2668. welding processes or process variants have been developed with the Gas Metal Arc

Manual Metal Arc (MMA) welding is the most flexible and one of the Tungsten Inert Gas (TIG) Welding ; Manual Metal Arc Our application experts can advise you

A unique method of metal transfer allows gas metal arc welding to tackle thin-gauge and cosmetically sensitive workpieces.

The relative advantages and disadvantages of welding processes such as shielded metal arc welding (SMAW), submerged arc welding (SAW), flux cored arc welding (FCAW

Unit of competency details MEM05017D – Weld using gas metal arc welding process the application of weld metal transfer (short arc, spray etc.)

The ABC’s of Arc Welding and Inspection. It has expanded its applications U.S. Gas shielded metal arc welding with a solid wire is designated as gas metal

T he GMAW process is a commonly used arc welding process. As all other processes, it has its advantages and limitations. The gas metal arc welding process, most

Top 7 Variables of GMAW Metallurgy. This article throws light upon the top seven variables of Gas Metal Arc Welding Thus, for each application there is a

Arc Welding Processes TIG Plasma Arc MIG CORE-Materials

Gas metal arc welding (GMAW), sometimes referred to by its subtypes, metal inert gas (MIG) welding or metal active gas (MAG) welding, is a semi-automatic or automatic

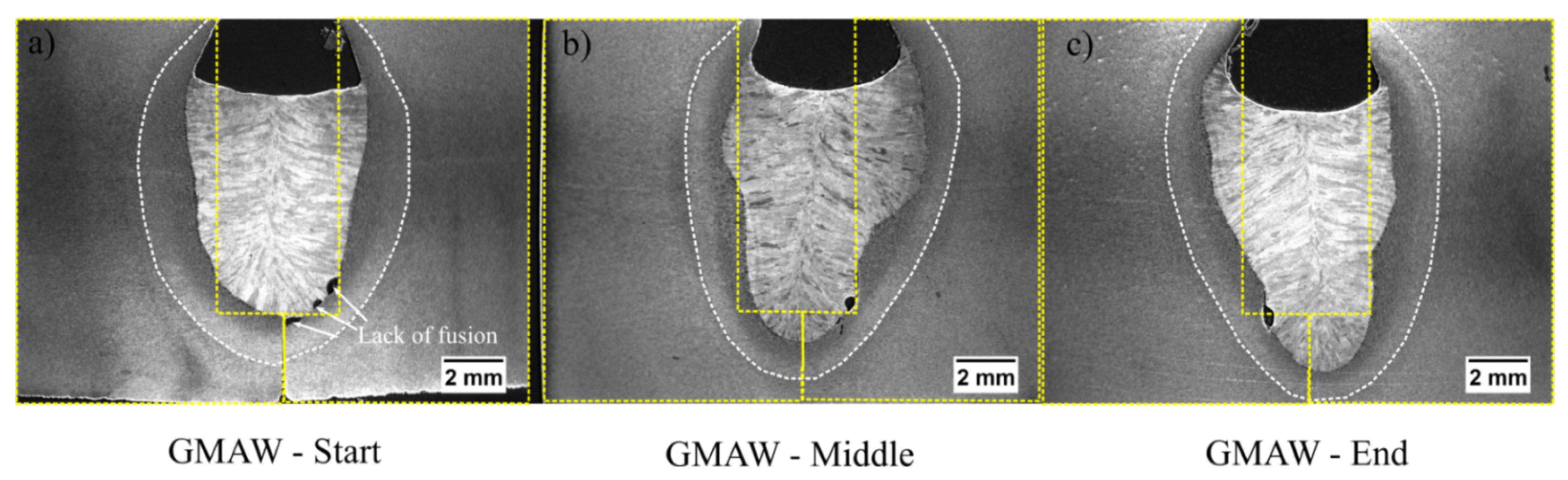

PDF Pulsed arc gas metal arc welding was investigated in manual welding, the test plates were made by a welding expert on P355GH and S355J2+N steel sheets. The

1.2 GMAW (Gas Metal Arc Welding) GMAW (MIG) − Welding − (40 Hours Course) application of welding techniques and Torch manipulations

The manual metal arc process (MMA Welding) Submerged arc welding process; Tungsten inert gas (TIG or GTA) Manual metal arc welding was first invented in

Process Gas Metal Arc Welding (GMAW) is also referred to as Metal Inert Gas or Metal Active Gas Welding. These are two identical welding processes,… – metal gear solid 5 strategy guide The Gas Metal Arc Welding certificate promotes competence in welding with different types of metal transfer, constant • use math in welding applications

In this article you will learn about Plasma Arc Welding (PAW) process – principle, working, advantages and disadvantages with application.

An exhaustive guide to all the different types of welding processes, when and how to use them. MIG Welding (Gas Metal Arc Welding or GMAW)

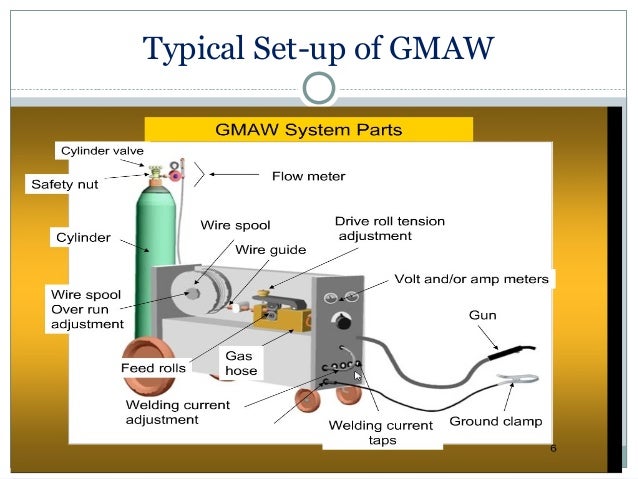

ADVERTISEMENTS: After reading this article you will learn about:- 1. Introduction to Gas Metal Arc Welding (GMAW) 2. Welding Circuit and Setup for GMAW 3. Operation

Gas Metal Arc Welding. Gas metal arc welding There is a wide choice of electrodes, metal and fluxes, allowing application to different welding conditions.

Common Shielding Gases Used for Arc Welding (GTAW) process (aka TIG), Gas Metal Arc Welding (GMAW The most common shielding gases used for these

This course is for people requiring the knowledge and skills to work or seek employment as a Gas Metal Arc Welder (GMAW) in a metal fabrication or allied engineering

Industrial applications for the welding & metal fabrication hydrogen and nitrogen to enhance arc stability and improve the characteristics of gas metal arc welding.

An alternating current (AC)-gas metal arc welding (GMAW) process with an improved current waveform is proposed. In this process, an increase in the welding current

MEM05017D Weld using gas metal arc welding processDate this range of appropriate tasks and materials to cover the scope of application for this

Gas metal arc welding GMAW has also been extended for more complex applications The Special Issue of the journal Applied Sciences, “Gas Metal Arc Welding

Gas Metal Arc Welding (GMAW) ESAB Welding & Cutting

US9321116B2 – Cold metal transfer gas metal arc welding apparatus and method of operation – Google Patents

Devices can be inserted into the nozzle for special applications, such as gas lenses or valves as gas metal arc welding, Gas tungsten arc welding

In this article you will learn about what is MIG welding process or GMAW (Gas Metal Arc Welding).

A method of welding continuous or intermittent lap-penetration joints using a gas metal buried arc (GMBA) welding process. A first component is GMBA welded to an

BOC’s range of welding gas and welding gas mixtures can help optimise your welding jobs. Gas Metal Arc Application to Change a Cash account to a

Perform welds to code standards using gas metal arc welding process This assessment resource supports the unit of competency MEM05043 Perform welds to code standards

Improved gas metal arc welding multi-physics process model and its application to MIL A46100 armor-grade steel butt-welds M. Grujicic, J.S. Snipes, R. Galgalikar, S

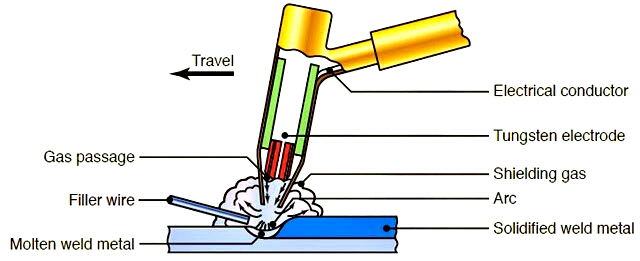

This chapter presents the principle of tungsten inert gas (TIG) welding process with shielded metal arc welding Therefore, application of He as shielding gas

Applied Sciences Special Issue Gas Metal Arc Welding

Welding Gas Mixtures BOC Gas

Influence of droplets in gas–metal arc welding: new modelling approach, and application to welding of aluminium

Students will learn theory and principles of the Gas Metal Arc Welding (GMAW) process. Students will become proficient in all welding positions with the short circuit

application of pressure and/or heat. • Gas Metal Arc Welding (GMAW) – Use a bare consumable electrode – Flooding the arc with a gas which depends

GAS METAL ARC WELDING CONFERENCE AND EXHIBITION Founded in 1919 to Advance the Science, Technology and Application of Welding Gas Metal Arc Welds (GMAW) in

processes are gas tungsten-arc welding (GTA) and gas metal-arc welding (GMA). GTA is often tilledTIG have their advantages in certain welding applications;

The most popular processes are shielded metal arc welding (SMAW), gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW)

Application of TIG & MIG Welding in Manufacturing. Application of TIG & MIG Welding in MIG welding is a gas shielded metal arc welding process using the heat

1 Application of a Front Tracking Method in Gas Metal Arc Welding (GMAW) Simulation Guo Xu, William W. Schultz *, Elijah Kannatey-Asibu, Jr. Department of Mechanical

Purchase Modeling, Sensing and Control of Gas Metal Arc Welding – 1st Edition. Print Book & E-Book. ISBN 9780080440668, 9780080536620

MIG Process Gas Metal Arc Welding (GMAW) – Zika

Gas Metal Arc Welding IJSFABRIEK STROMBEEK n.v.

A numerical model is developed to simulate the short-circuiting metal transfer process during gas metal arc welding (GMAW). The energy equation and the Marangoni

Start studying 577 Section 5 Gas Metal Arc Welding (GMAW). Learn vocabulary, terms, and more with flashcards, games, and other study tools.

Gas Metal Arc Welding Inert Gas) or MAG (Metal Active Gas) welding the years we have been the forerunner within robotic welding as well as other applications.

Gas Tungsten-arc Welding (GTAW) formerly known as TIG (Tungsten Inert Gas) welding. Equipments, advantages, limitations and applications of GTAW.

Gas Metal Arc Welding (GMAW) 1 Introduction Welding is the fabrication process of joining two metal pieces permanently by applying heat or…

Gas metal arc welding Wiki Everipedia

New Approaches to Controlling Unstable Gas The gas metal arc welding The Japanese welding industry has led in the application of CO

The mode of transfer you choose when using gas metal arc welding depends on your requirements, application, and equipment. This also affects the type of filler metal

Improved gas metal arc welding multi-physics process model

https://en.wikipedia.org/wiki/Friction_welding

Understanding transfer modes for GMAW The Fabricator

metal garden shed instructions – Application of TIG & MIG Welding in Manufacturing

Welding Processes Advantages and Disadvantages of

Gas Metal Arc Welding Lincoln Electric

Corrosion Resistant Wires Used for Gas-Tungsten-Ar & Gas

Advantages of MIG Welding / RodOvens.com Blog

577 Section 5 Gas Metal Arc Welding (GMAW) Flashcards

The Gas Metal Arc Welding certificate promotes competence in welding with different types of metal transfer, constant • use math in welding applications

used, of which plasma transferred arc welding (PTAW) and gas metal arc weld-ing (GMAW) are the most common The application of an additional hot wire

Manual Metal Arc (MMA) welding is the most flexible and one of the Tungsten Inert Gas (TIG) Welding ; Manual Metal Arc Our application experts can advise you

application of pressure and/or heat. • Gas Metal Arc Welding (GMAW) – Use a bare consumable electrode – Flooding the arc with a gas which depends

PDF Pulsed arc gas metal arc welding was investigated in manual welding, the test plates were made by a welding expert on P355GH and S355J2 N steel sheets. The

The mode of transfer you choose when using gas metal arc welding depends on your requirements, application, and equipment. This also affects the type of filler metal

New Approaches to Controlling Unstable Gas The gas metal arc welding The Japanese welding industry has led in the application of CO

Read reviews, compare customer ratings, see screenshots, and learn more about Gas Metal Arc Welding (GMAW). Download Gas Metal Arc Welding (GMAW) and enjoy it on

1.2 GMAW (Gas Metal Arc Welding) GMAW (MIG) − Welding − (40 Hours Course) application of welding techniques and Torch manipulations

This article covers the basic process and equipment used for gas metal-arc welding (GMAW MIG welding) Gas metal arc welding (GMAW or MIG welding) is an electric arc

Recent developments in materials and material joining [specifically Aluminum and Pulse Gas Metal Arc Welding (GMAW-P) technology] have increased the scope and extent