Sheet metal product design pdf

Sheet metal product design pdf

Sheet Metal Design Guidelines – SMLease Design To develop better quality parts at reduced cost, some of the common sheet metal design guidelines like: minimum distance between holes, cutouts, slots, distance between holes, cutouts, slots to part edge and bends, multiple bends in same direction, minimum bend radius need to be followed.

Sheet Metal Design Handbook. Australian Design & Drafting Services create sheet metal part designs using SOLIDWORKS 3D design and Autodesk Inventor, accelerating the design process, saving time and development costs, and increasing productivity.

NX 9 for Beginners – Part 5 (Sheet Metal Design) Pdf mediafire.com, rapidgator.net, 4shared.com, uploading.com, uploaded.net Download Note: If you’re looking for a free download links of NX 9 for Beginners – Part 5 (Sheet Metal Design) Pdf, epub, docx and torrent then this site is not for you.

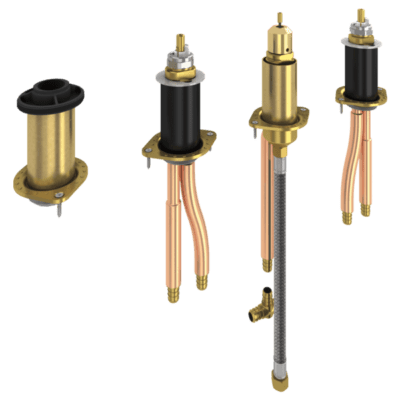

Most sheet metal fabricators also include purchased materials such as hardware, gasketing, other components purchased for the product that is shipped to the customer.

BlueScope Sheet Metal Supplies is a market leading sheet metal business focused on providing quality aluminium and steel products to the Australian market

China Sheet Metal manufacturers – Select 2018 high quality Sheet Metal products in best price from certified Chinese Metal Stamping manufacturers, Cast Iron …

3D Conceptual Design of Sheet Metal Products by Sketching

Expanded Metal T Safe Flooring Solutions echnical Design

NX Sheet Metal Design.pdf – Download as PDF File (.pdf), Text File (.txt) or read online. CAD

With the booming need to enhance the product quality and finishing, testing different metallurgy at affordable cost, sheet metal fabricators demand accurate fabrication drawings. To achieve the cost control and reduced design iterations and testing with physical prototypes, we deliver high-quality

MEM09219A Prepare drawings for fabricated sheet metal products Modification History ReleaseUnit Descriptor 1 – New unit of competency This unit of competency covers the skills and knowledge required to prepare detail drawings for fabrication of sheet metal products. Application of the Unit This unit would be applied by draftspersons operating within the manufacturing and engineering industry

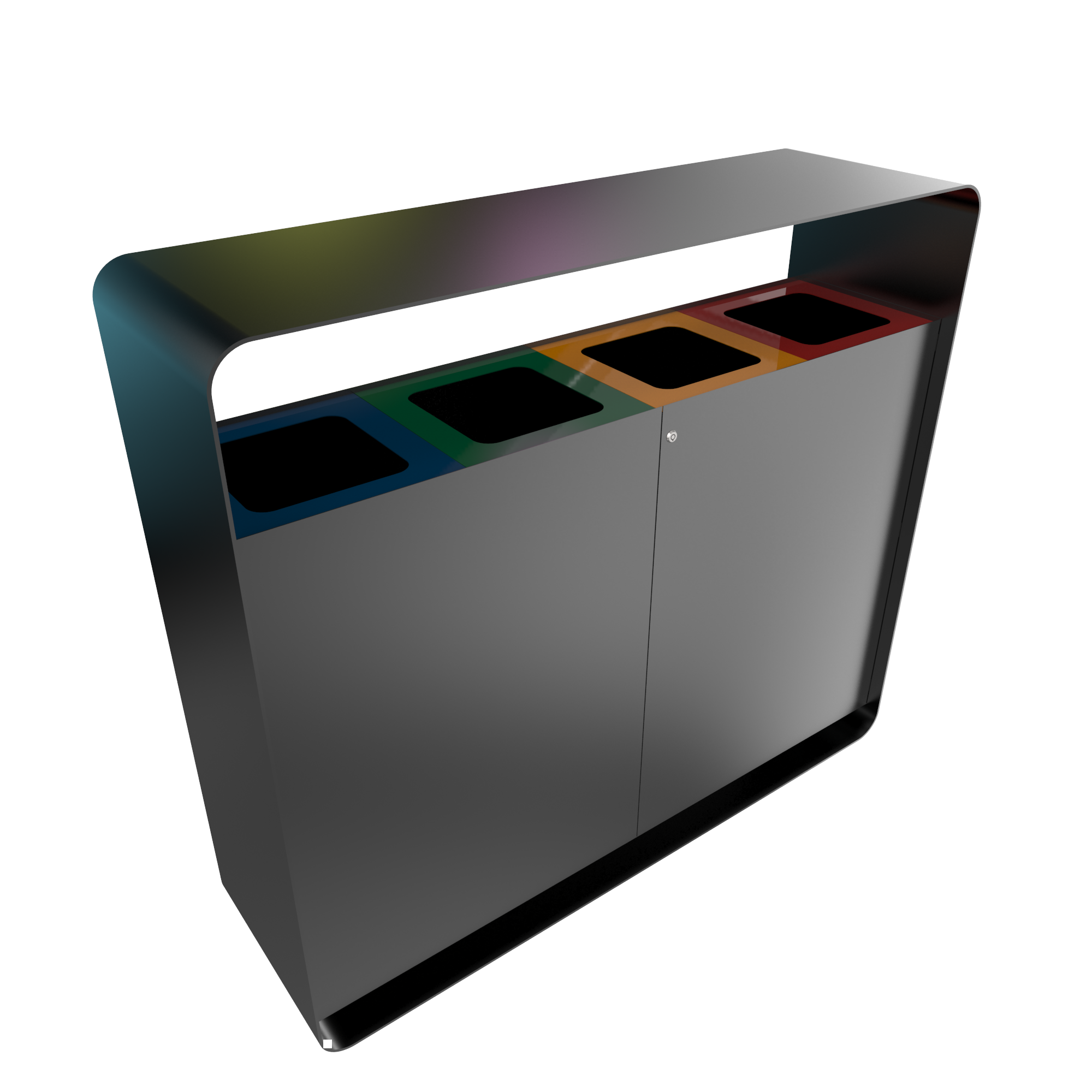

Sheet Metal Products & Components. FORM2000 invests in ensuring we offer the latest in sheet metal factory automation technology allowing us to run high mix, and varying volume of OEM sheet metal components to meet the needs of multiple sheet metal OEM clients and/or product variations.

A sheet metal’s ability to withstand stress in a flexure test is an essential facet of sheet metal design. Depending on the process adopted for bending, the K-factor in the area of bending is usually visualized. In the course of bending, the outer surface of the sheet metal witnesses more strain than the inner surface. Bending the sheet metal beyond a point would result in cracks on the

The V5 CATIA – Sheet Metal Design is a new generation product offering an intuitive and flexible user interface. It provides an associative feature-based modeling making it possible to design sheet metal parts in concurrent engineering between the unfolded or folded part representation. As a scalable product, CATIA Version 5 Sheet Metal Design can be used in cooperation with other current or

Advance Metal Products is Australasia’s leading sheetmetal manufacturer, utilising the latest CNC sheet metal technology to provide superior quality components and products, with reduced lead times, at competitive prices. Advance Metal Products is located in Sydney, New South Wales, Australia.

Sheet metal product design and development of a family of enclosures. One of our existing clients asked us to help with a new sheet metal product design for …

Design for Sheet Metal Forming Processes . Instructional objectives . By the end of this lecture, the student will learn the principles of several sheet metal forming processes and measures to be taken during these process to avoid various defects. Sheet Metal Forming Processes . Sheet metals are widely used for industrial and consumer parts because of its capacity for being bent and formed

In keeping with its policy of disseminating information and providing standards of design and construction, the Sheet Metal and Air Conditioning Contractors’ National Association, Inc. (SMACNA), offers this comprehensive fundamental HVAC Systems−Duct Design manual as part of our continuing effort to upgrade the quality of work produced by

Link Dwonload Manufacturing Integrated Design Sheet Metal Product And Process Innovationintegrated Production Control Systems Management Analysis Design ,Read File Manufacturing Integrated Design Sheet Metal Product And Process Innovationintegrated Production Control Systems Management Analysis Design pdf live , Where I can Download Manufacturing Integrated Design Sheet Metal Product …

Product Design Estes engineers bring years of sheet metal fabricating experience to bear on even the most complex problems. With the ability to anticipate and resolve manufacturing challenges even before the process is begun, Estes insures the development of …

Design For Manufacturing/Assembly (DFM, DFA, DFMA) Much of the early and significant work on DFM and DFA was done in the early 1970s by Boothroyd and Dewhurst. Traditionally, product development was essentially done in several stages. The designer(s) (who usually had very good knowledge of materials, mechanisms, etc.) would design the product, and sometimes would …

The book gives a systematic and detailed description of a new integrated product and process development approach for sheet metal manufacturing. Special attention is given to manufacturing that unites multidisciplinary competences of product design, material science, and production engineering, as

A sheet metal part is often thought of as a part fabricated from a sheet of uniformly thick material. If you design small objects, this material is often thin. However, in If you design …

Testing was conducted in accordance with AS 1562.1—1992 design and installation of Sheet Roof and Wall Cladding—Metal, and AS 4040.2— 1992 Resistance to Wind pressure for non-cyclonic Regions.

NX Sheet Metal Strengths – NX 6 Complete suite of features for sheet metal design Value: ability to design almost any straight-break sheet metal

Autodesk Inventor Sheet Metal Design introduces the concepts and techniques of sheet metal modeling with the Autodesk Inventor software. The structure of the course follows the typical stages of using Inventor. That is, to create sheet metal parts, edit them, generate flat patterns, and document the designs in drawings. The major topics covered include: • Autodesk Inventor Sheet Metal

Creo 2.0 Sheetmetal Design for Mechanical Design Engineers,Engineers,Students Advanced Sheet metal Design in Creo 2.0 • Introduction to Sheet metal Process• Create unattached flat walls.• Create reliefs in the sheet metal component.• Create a flat wall.• Create the twist wall and the extend wall.• Add flange walls to sheet metal

For Sheet metal design engineer position in sheet metal product design or sheet metal manufacturing company, interviewer may ask questions on For Sheetmeta sheet-metal manufacturing and design. To clear sheet-metal design engineer interview you should be aware of basic fundamentals of sheetmetal design .

Stylish Metal Box Building Made in a Small Building Concept and Design: Unique Wall Design In Modern Cubic House With Theme Of Holes Which . Tego Pina i nie tylko znajdziesz na tablicy Sheet metal użytkownika Konrad Pietrykowski.

Design For Manufacturability – Sheet Metal Guidelines Bends For the ease of manufacturing, multiple bends on the same plane should occur in the same direction. Avoid large sheet metal parts with small bent flanges. In low carbon steel sheet metal, the minimum radius of a bend should be one-half the material thickness or 0.80 mm (0.03 inch), whichever is larger. Bends specified as angles may

SHEET METAL CATALOG Excelsior

Manufacturing Reference for Sheet Metal Products This reference guide is intended to provide current process capabilities of the sheet metal industry. The tolerances specified in this document are the minimum available without specialized tooling or processes. Tolerances should be made as broad as possible, while retaining high product quality and functionality. Focus should be on maintaining

Sheet Metal Design With Inventor. The Best Sheet Metal Design With Inventor Free Download PDF And Video. Get Sheet Metal Design With Inventor: Get Free & Instant Access To Over 150 Highly Detailed Woodworking Project Plans.

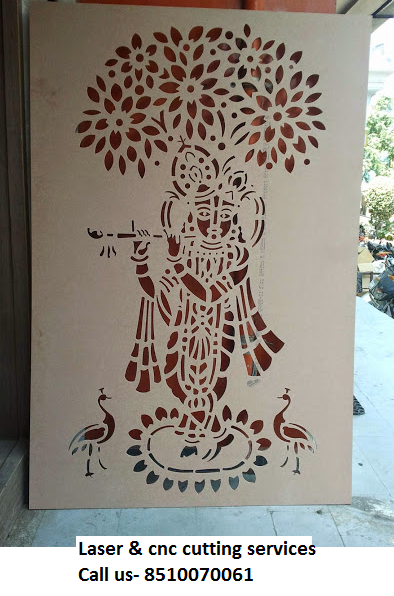

Sheet metal – design of a beautiful corner detail Using sheet metals in Product Design seems a little out of fashion compared with Injection Moulded parts. This is a pity because sheet metal, designed and used properly, is a very good material for sturdy parts that …

This study will concentrate on Product Data Management (PDM) systems, and sheet metal design features and classification. In this thesis, PDM is seen as an individual system which handles all

NEW CONSTRUCTION OR RE-DEVELOPMENT This aesthetically pleasing panel system is fixed directly to furring channels adding flexibility to its application.

3D Conceptual Design of Sheet Metal Products by Sketching M. Shpitalni, H. Lipson Laboratory of Computer Graphics & CAD, Faculty of Mechanical Engineering

NX Sheet Metal Design. Accelerating design of sheet metal components of any complexity Benefits • Intuitive user interface results in reduced learning curve • Streamlined workflow requires less time for part design Features • Built-in design intent using a focused sheet metal workflow • Customer-defined default values • Intuitive user

Design Sheet Metal is the market leader in the supply of flashings and rainwater related products. We fastest turn around times. Our operating hours are set in order to deliver the highest customer service, operating 24 hours per day.

As per sheet metal design thumb rules, the length of bend relief should be greater than or equal to the inside bend radius of the bend and the width of the bend relief should be greater than or equal to the sheet metal thickness.

The principle of uniform product thickness. Sheet metal is a uniform thickness of the material, should pay attention to the structure design, especially in the bending places, it is easy to cause uneven thickness. The principle of easy flattening. Sheet metal products are processed from the sheet, in the absence of processing, the raw materials are flat, so in the design of sheet metal parts – universal metal bender instructions sheet of material becomes expanded metal without waste. The result of this expanding operation is a product that is lighter and stronger than the original sheet or plate from which it came.

Mallik Multitechnologies is a one stop solution shop for all Sheet Metal Products and Services specializing in all aspects from Design to Fabrication and Services

2 ABSTRACT This paper describes an integrated system for the design and production of sheet metal parts. We have identified some important features for the sheet metal bending process.

PRODUCT DRAWING INDEX. We have three types of architectural metal drawing files that can be downloaded. PDF: Click on the PDF file type to open in your browser/computer or you can right click on the PDF file type to “Save Target As” to your computer.

In the today’s industry the sheet metal design plays an important role, it has been said that almost the half of the designing is concentrating to sheet metals.

For a large sheet metal product manufacturer or fabricator, this is even more important as there are chances of multiple supply chain vendors involved in the product development. There are chances that design information from each of them would come from …

Sheet metal enclosures are fabricated by ‘cold forming’, where the metal is clamped and bent in machines called ‘press brakes’. As a result, metal typically cannot be formed into a true 90 degree corner. Instead, the corners are curved.

As part of our standard remit, we offer sheet metal product design & development projects. We work closely with our clients to understand their exact needs and will discuss any project looking to come up with the most suitable solutions.

Many engineers developing 3D models for sheet-metal products are unaware of the fabrication tools used to form the part or product, and instead design models for an “ideal” world. In the ideal

Sheet metal product design & development A & R Engineering

Sheet Metal Product Design devon3dcad.co.uk

#1 Sheet Metal Design With Inventor Free Download PDF Video

Sheet Metal Design Icon (Computing) Technical Drawing

sheet metal design services Hi-Tech

PREMIUM ALUMINIUM PRODUCTS Bluescope Sheet Metal

Mechanical Design Tutorial SHEETMETAL DESIGN

SHEET METAL DESIGN HANDBOOK Hire DraftsmanDesign and

effect of metal coupling on rusting of iron pdf – DESIGNER PANEL SYSTEMS VERSACLAD Design Sheet Metal

Advance Metal Products Sheet Metal Fabrication

Contact Us Sheet Metal Product Design Bangalore

Sheetmetal Design Interview Questions Mechanical