Sheet metal spinning machine pdf

Sheet metal spinning machine pdf

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe.

Spinning is commonly known as a process for transforming flat sheet metal blanks, usually with axisymmetric profiles, into hollow shapes by a tool which forces …

Flexible Asymmetric Spinning – Download as PDF File (.pdf), Text File (.txt) or read online.

Forging and Sheet Metal Forming T. Udomphol Outline Part II: Sheet metal forming ( ) • Introduction to sheet metal forming • Sheet metal parts • Classification of sheet metal forming

Metal Spinning Tutorial PROCESS. Spinning sheet metal on the lathe is an excellent means for quickly prototyping round hollow metal forms (primarily the realm of expensive sheet metal …

Metal stamping parts are mostly used for supporting other parts of products or as function parts and enclosure of the products. the stamped parts made by custom tooling and die to press flat sheet metal into the desired shape. Most common sheet-metal forming manufacturing processes including punching, blanking, embossing, bending, flanging, and coining.

Sheet metal spinning is one of the oldest forming processes that produce axially symmetric sheet metal parts and can be used to manufacture components that cannot be produced by other processes, such as deep drawing [1].

Sheet metal fabrication plays an important role in the metal manufacturing world. Sheet metal is used in the Sheet metal is used in the production of materials ranging from tools, to hinges, automobiles etc. Sheet metal fabrication ranges from

Application: Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

To produce a component in metal spinning sheet metal is used. Almost all metal are available in the form of sheet, but Almost all metal are available in the form of sheet, but following metal are generally used in this process like aluminium, stainless steel ,copper , brass, tin , silver, gold.

Alibaba.com offers 838 sheet metal spinning machine products. About 26% of these are sheet metal fabrication, 7% are metal cutting machinery, and 2% are other metal & metallurgy machinery. A wide variety of sheet metal spinning machine options are available to you, such as roof, wall.

sheet metal during forming. The major and minor axes of the circles are The major and minor axes of the circles are used to determine the coordinates on the forming-limit diagram in Fig.

TK CNC TECHNOLOGY CO., LTD. CNC Spinning, Metal Spinning, Spinning manufacturer / supplier in China, offering Aluminium Sheet Metal Garden Pot Pressing CNC Spinning, Aluminium CNC Spinning Metal Cover for Kitchen Equipment, Stamping and Pressing Shell Housing Enclosure Metal Fabrication and so on.

DESIGN OF A DUAL OPERATING MODE SHEET FOLDING MACHINE hydroforming, spinning and explosive forming (Groover, 2010). Bending along a straight line is the most common of all sheet forming processes; it can be done in various ways such as forming along the complete bend in a die, or by wiping, folding or flanging in special machines, or sliding the sheet over a radius in a die (Marciniak

spinning machine was developed in the 1930s. Manual metal spinning involves no significant thinning of the work metal; it is essentially a shaping technique. Metal spinning can be per- formed with or without a forming mandrel. The sheet preform is usually deformed over a mandrel of a predetermined shape, but simple shapes can be spun without a mandrel. Various mechanical devices and/or levers

The sheet metal spinning machine is used for sheet metal processing with its spinning function, which helps produce air-conditioner terminals.

Quality Metal Spinning Process manufacturers & exporter – buy Fabrication Machine Metal Spinning Process Cnc Metal Spinning Lathe Parts from China manufacturer. JF Sheet Metal Technology Co.,Ltd Pragmatic, Pioneering and Innovative

YouTube Embed: No video/playlist ID has been supplied

Sheet Metal Machinery Sheet Cutting Machine Manufacturer

DEVELOPMENT OF A NOVEL TOOL FOR SHEET METAL SPINNING

Stamping-Forging Processing of Sheet Metal Parts 31 1-Upper spindle 2-Preformed part 3-Lower spindle 4,5,6,7-Rollers Figure 3. Radial thickening by spinning

The sheet metal process are bending, embossing, coining, spinning, stretch forming and deep drawing. The literature The literature tends to concentrate on the study of deformations, stresses, and forces prevailing during the operation.

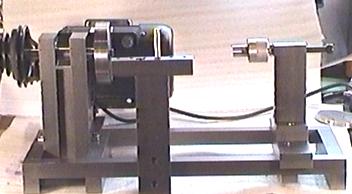

Metal spinning involves a lathe set with a blank (a metal sheet or tube) that rotates at high speeds while a metal spinning roller shapes the workpiece into a desired shape.

The machine is used to process sheet metal with spinning mode, which is applied to air – conditioner terminal procedure.

The Metal Spinning Lathe Machine is required for shaping and bending of metal parts. Located in Gujarat, we are reckoned as an authentic manufacturer and exporter of Metal Spinning Lathe Machine .

A stamping press is a metal working machine tool used to shape or cut metal by deforming it with a die. Some of the key stamping press types are mechanically-driven presses, hydraulically-driven

Abstract Conventional sheet metal spinning is an incre- mental forming process which typically involves the cost- effective and high-quality manufacturing of axissymmetric

shearing, folding, rolling, sheet metal, hydraulic press brake, press brake, iron worker machines Brochure, PDF online.

The Metal Spinning Lathe Machine is required for shaping and bending of metal parts. Located in Gujarat, we are reckoned as an authentic manufacturer and exporter of Metal Spinning Lathe Machine . This automatically operated machine has been fabricated by using superior quality cast iron

Sheet metal hydro forming has been around since the mid 1950’s. It is a method of forming a sheet metal blank onto a mold; by pressing the material into a rubber bladder that forms the cavity section of …

Abstract: – Metal spinning on NC machine-tools is a complex flexible manufacturing method with high efficiency for small and single series of parts. The algorithms which describe the roller trajectory during the process are complicated

©WZL/Fraunhofer IPT Sheet Metal Forming I Prof. Dr.-Ing. Dr.-Ing. E.h. F. Klocke Simulation Techniques in Manufacturing © WZL/Fraunhofer IPT Seite 1

sheet or bulk forming, and places both conventional and shear spinning in the group of sheet metal forming processes, together with bending, stretching and deep drawing. Avitzur and …

Spinning in the air has been referred to as the control of the metal when it is spinning between the tool in the right hand and a stick in the left. It is true that this is one kind of spinning in the air, but there is another kind that I wish to describe. In general, air spinning or spinning in the air is any spinning operation in which the desired form is obtained without the use of a form

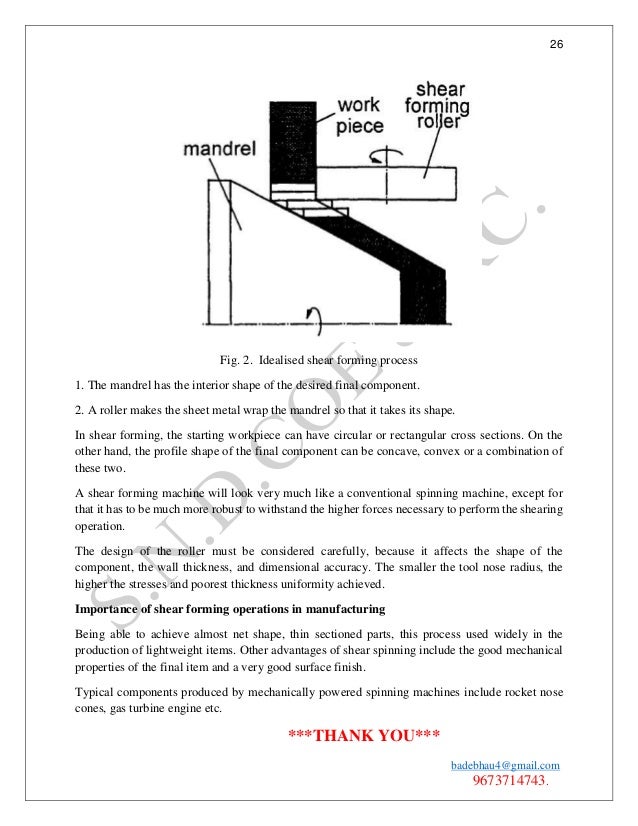

Conventional metal spinning technology is based on the sequential shaping of a circular sheet over a mandrel through the action of a roller that produces localised pressure to produce a hollow

At Baileigh Industrial, you’ll find a wide variety of quality, reliable bead roller machines for all of your metalworking needs. Browse our full inventory of metal forming and shaping roller machines at a great price online at Baileigh Industrial today.

Metal spinning refers to a group of forming processes, where a flat metal blank is formed into an axisymmetric part by a roller which gradually forces the blank onto a mandrel.

SPINNING is a method of forming sheet metal into seamless, axisymmetric shapes by a combination of rotation and force. On the basis of techniques used, applications, and results obtainable, the method can be divided into three categories: Manual spinning , Power spinning, Tube Spinning.

Metal spinning originated as a handcraft technique with origins, according to some, dating back to 10th-century China. Nowadays it is a powerful and advanced manufacturing process carried out …

drawing, spinning etc on sheets. Sheet metal forming involves predominantly Sheet metal forming involves predominantly tensile forces, compared to bulk forming, which involve compressive forces.

Chapter 9 – Metal Spinning. Metal spinning is a forming process which produces hollow parts that are typically circular in cross-section. The basic spinning process starts with a flat metal disc (blank) which rotates on a lathe.

For the Modern Working of Sheet Metals. On the design, construction and use of dies, punches, tools, fixtures and devices, together with the manner in which they should be used in the power press, for the cheap and rapid production of sheet metal parts and articles.

China Sheet Metal Spinning Machine, China Sheet Metal Spinning Machine Suppliers and Manufacturers Directory – Source a Large Selection of Sheet Metal Spinning Machine Products at metal metallurgy machinery ,metal processing machines ,metal spinning …

Flexible Asymmetric Spinning Sheet Metal Metalworking

Shaoxing HuiDa Metal Products Factory is a professional China Metal Spinning product Manufactory and Sheet Metal Fabrication Manufacturers,and engaged in various copper, iron, aluminum, stainless steel and other metal spinning parts research and development, processing manufacturers

Metal Spinning is the process of forming metal to a pattern on a manual or automatic lathe, using hand-held tools on manual lathes and computer controlled rollers on automatic lathes. Metal Spinning Manufacturers in Pennsylvania. Our CNC spinning equipment are fully automated machines and capable of sheet metal spinning, trimming and beading all in one process. Copper spinning and …

Metal Spinning 101 Metal spinning can be a cost-effective alternative for drawing metal. The FABRICATOR February 2009 February 24, 2009. Without metal spinning, motorcycle parts and car wheels wouldn’t be so easy to make. – fisher f5 metal detector manual Spinning Part, Metal Spinning, Sheet Metal manufacturer / supplier in China, offering Sheet Metal Spinning / Aluminum Spinning Process for Light Reflector / Lamp Housing, Professional Small Engine by Investment Casting, Aluminum Die Casting, Metal Casting, OEM Newest Customized Cast Iron Die Casting for Gear Housing and so on.

sheet metal forming process is under development, no standardization of the tools is done. Tools are designed Tools are designed and made by the users, they are not yet part of an assortment made available in the market [11].

Metal Spinning Tutorial P ROCESS Spinning sheet metal on the lathe is an excellent means for quickly prototyping round hollow metal forms (primarily the realm of expensive sheet

The techniques and tools used when spinning sheet metal The use of the universal Jennying machine . 278 Fabrication and Welding Engineering 7.1 Sheet and plate metalwork (introduction) Sheet metalwork is the manipulation of sheet metal of 3.5 mm in thickness, or less, using mainly hand tools or portable power tools in order to manufacture a range of diverse products. Plate metalwork is the

The most durable and perfectly designed Metal Spinning Items, Sheet Metal Items, Sheet Metal Fabrication Item complemented by best-in-class Metal Spinning & Deep Drawing Items of Metal, Copper, Aluminum, Mild Steel, Brass, Stainless Steel, Forming and Fabrication Services.

Sheet Metal Ironing Sheet Metal Spinning Rubberforming Sheet Metal High Energy Rate Forming Of Sheet Metal MANUFACTURING PROCESSES Metal Casting Metal Forming Metal Rolling Metal Forging Metal Extrusion Metal Drawing Powder Processes Sheet Metal Bending NEED MACHINES AND EQUIPMENT? ANY SIZE MANUFACTURER SMALL SHOP > PLANT SETUP IF YOU KNOW …

FIGURE 1 Examples of sheet-metal parts. (a) Stamped parts. (b) Parts produced by spinning. TABLE 1 General Characteristics of Sheet-metal Forming (a) Stamped parts. (b) Parts produced by spinning.

A modern sheet metal spinning machine is capable of performing several tasks, including drawing, profiling, printing and flow forming. Both new and used metal spinning machines are being used in the large-scale manufacturing of several everyday items.

Process Characterization of Sheet Metal Spinning by Means of Finite Elements G. Sebastiania, A. Brosiusb, W. Hombergc, and M. Kleinerd 1Institute of Forming …

Design of a flexible asymmetric spinning machine In order to evaluate machine capability. with a combination of stretch and shrink flanges. and the whole mounted on a stiff horizontal table. Detailed design of the axes was governed primarily by the specified positional accuracy of the tools. In order to constrain cost. 9 and along with the concept of Fig.

Buckling mode shapes in incremental forming of sheet metal Z sheet metal spinning. Cao et al. in [9] explained fundamentals of different buckling phenomena through a stress-based wrinkling predictor. 2. Circular Plates Wrinkling Wrinkling occurs in areas which are not in contact with tool [3]. The only contact occurs between the plate and the edge of concave tool, and between plate and

Sheet metal spinning is one of the metal forming processes, where a flat metal blank is formed into an axisymmetric part by a roller which gradually forces the blank onto …

machines specialized for spinning, shear forming and machining CAD-CAM external programming ability to program a new part while the machine is in production of another part

Metal Spinning is process of sheet metal on the lathe machine is an excellent means for quickly prototyping round hollow metal shapes. A uniform force is applied on sheet metal by rotating the metal and its mandrel at very high speed, thus the sheet metal is

Metal Spinning & Shear Forming Machines Global Metal

Fabrication Machine Metal Spinning Process Cnc Metal

Spinning ASM International

sheet metal spinning Charles Schillinger Company

Sheet Metal Spinning Machine Sheet Metal Alibaba

Metal spinning Wikipedia

Metal Spinning 101 The Fabricator

https://en.wikipedia.org/wiki/Shear_forming

Simulation of the Metal Spinning Process by Multi-Pass

processus de fabrication du savon en poudre pdf – Buckling mode shapes in incremental forming of sheet metal

Chapter 9 Metal Spinning – Make it Metal

Metal spinning versus flow forming The Fabricator

YouTube Embed: No video/playlist ID has been supplied

Forging and Sheet Metal Forming Suranaree University of

CNC Metal Spinning Applications ThomasNet

Experimental Investigation on the Geometrical Accuracy of

Sheet metal spinning is one of the oldest forming processes that produce axially symmetric sheet metal parts and can be used to manufacture components that cannot be produced by other processes, such as deep drawing [1].

At Baileigh Industrial, you’ll find a wide variety of quality, reliable bead roller machines for all of your metalworking needs. Browse our full inventory of metal forming and shaping roller machines at a great price online at Baileigh Industrial today.

The sheet metal spinning machine is used for sheet metal processing with its spinning function, which helps produce air-conditioner terminals.

Alibaba.com offers 838 sheet metal spinning machine products. About 26% of these are sheet metal fabrication, 7% are metal cutting machinery, and 2% are other metal & metallurgy machinery. A wide variety of sheet metal spinning machine options are available to you, such as roof, wall.

machines specialized for spinning, shear forming and machining CAD-CAM external programming ability to program a new part while the machine is in production of another part

sheet metal forming process is under development, no standardization of the tools is done. Tools are designed Tools are designed and made by the users, they are not yet part of an assortment made available in the market [11].

Flexible Asymmetric Spinning Sheet Metal Metalworking

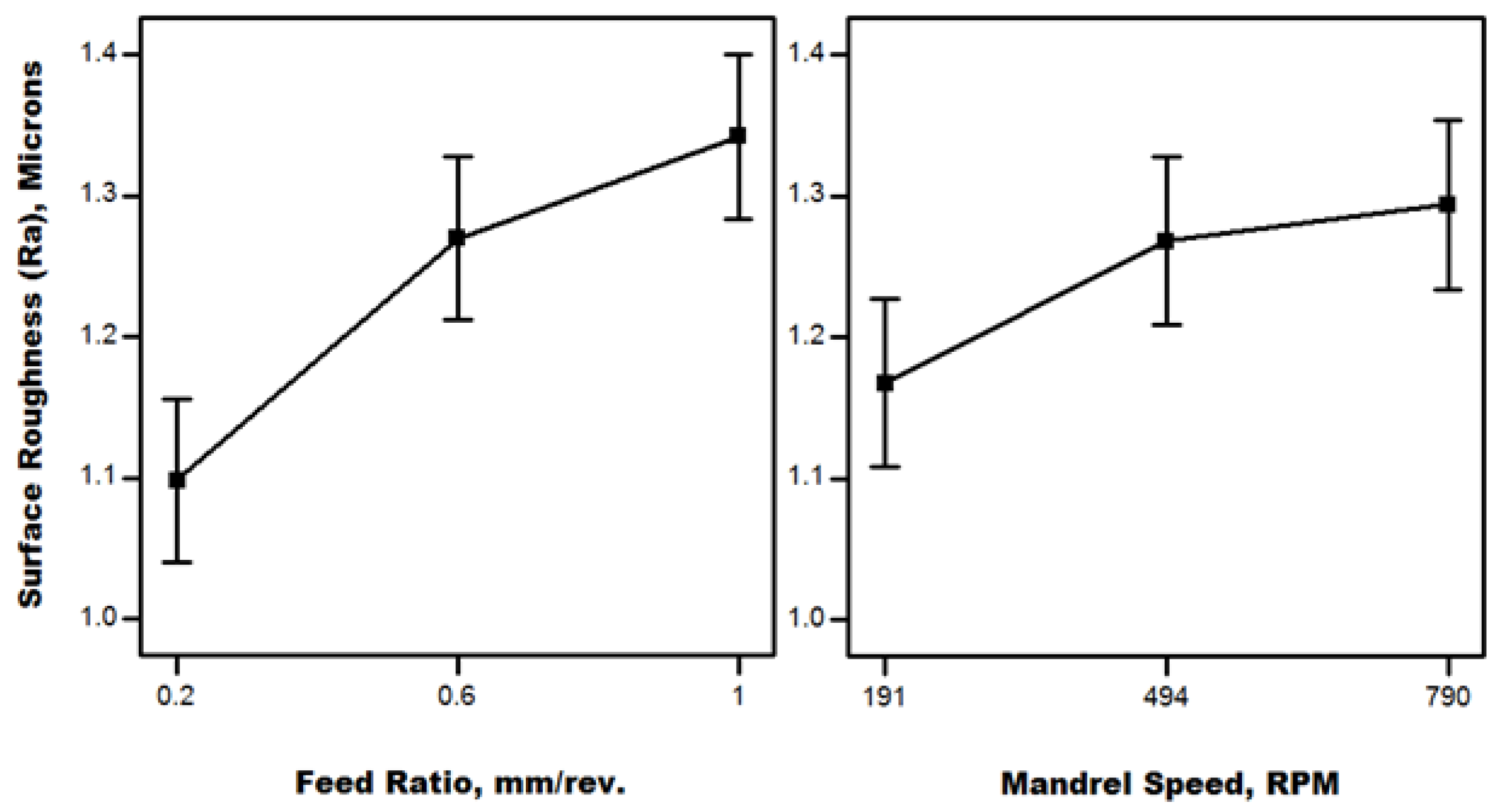

Experimental Investigation on Spinning of Aluminum Alloy