Types of metal cutting tools pdf

Types of metal cutting tools pdf

Cutting tools with inserts (indexable tools) Cutting tools are often designed with inserts or replaceable tips ( tipped tools ). In these, the cutting edge consists of a separate piece of material, either brazed, welded or clamped on to the tool body.

Metal cutting is “the process of removing unwanted material in the form of chips, from a block of metal, using cutting tool”. A person who specializes in machining is called a machinist. A room, building or company where machining is done is called a Machine Shop.

to all types of metal cutting tools. It is now undertaking preparation of the more general standard. In September 1960, Technical Committee 29 of the International Standards Organization (ISO) had established Working Group 20 on Geometry of the Active Parts of Cutting Tools and this group became active in December 1962. Earlier in 1962, TC16 had begun cooperation with the committee dealing

After reading this article you will learn about:- 1. Meaning of Tool Wear 2. Types of Tool Wear 3. Causes 4. Growth 5. Forms 6. Consequences. Cutting tools are subjected to an extremely severe rubbing process. They are in metal-to-metal contact between …

Hand tools used to cut sheet metal, there are two different types of snips, tinner snips and compound action snips. Tin snips have long handles and short blades and are generally used to cut low carbon tin or mild steel. Straight pattern tin snips are ideal for cutting straight lines or gentle curves, whilst duckbill pattern tin snips are ideal for cutting sharper curves. There are also tin

tools, free cutting steel, tools for wood machining twist drill and tapping tools, milling tool, reaming tool, broaching tool end milling tools, turning tools for free cutting operations, twist drills,

Keywords: thermal cutting, oxygen cutting, oxygen lance cutting, oxyfuel cutting, chemical flux cutting, metal powder cutting, arc cutting, carbon arc cutting, shielded metal arc cutting, gas tungsten arc cutting, plasma arc cutting, beam cutting, laser beam

INTERNAL COOLING OF METAL-CUTTING TOOLS Introduction FOR many years, attempts have been made to reduce the temperature of metal-cutting tools. All types of liquids, gases and mists have been used in order to make the tool run cooler. The reason for this is that a lower temperature cutting tool will not wear as rapidly and therefore has a longer useful life. This has been shown by many workers

to remove metal from the piece being machined. The screw cutting lathe originates in the 17th century. Development and advancements have continued and today we have sophisticated computerized controlled lathes. Lathes have allowed man to reshape, machine and manufacture many precision cylindrical components made of various types of metal, wood, plastics, and other materials. Without …

Chip formation is part of the process of cutting materials by mechanical means, using tools such as saws, lathes and milling cutters. An understanding of the theory and engineering of this formation is an important part of the development of such machines and their cutting tools.

THEORY OF METAL MACHINING •Overview of Machining Technology •Theory of Chip Formation in Metal Machining •Force Relationships and the Merchant Equation •Power and Energy Relationships in Machining •Cutting Temperature ©2002 John Wiley & Sons, Inc. M. P. Groover, “Fundamentals of Modern Manufacturing 2/e” Material Removal Processes A family of shaping operations, the common

Turning. Turning is basically a lathe operation by which the metal is removed from the workpiece outside its diameter using a cutting tool. This operation is performed on a lathe which is a machine where the workpiece is adjusted and the tool is kept stationary whereas the workpeice is rotated.

11/12/2018 · These cutting tools can also be used horizontally or vertically, either approaching or rotating around a stationary piece of metal. The bit might also be fixed, with a conveyor type of setup bringing the metal to the cutter.

This tool, also known as a “Fly Cutter”, uses a flying cutting bit to cleanly cut holes in metal, wood, plastic, and hardwoods from 1” to 5-1/2” diameter. The included 1/4”

• Types and properties of cutting-tool materials • • Tool materials • Metal cutting fluids • Cutting machine characteristics • Vibration and chatter • Cutting economics. Summary of Machining Chapter • Deep understanding • Chip formation mechanisms • Merchant orthogonal cutting model • Cutting forces and specific energy • Tool wear: mechanisms, tool life

Continuous chips are formed by the continuous plastic deformation of metal without fracture in front of the cutting edge of the tool and is formed by the smooth flow of the chip up the tool face.

(PDF) Manufacturing Technology Vol. 2 Metal Cutting and

Cutting Tool Materials ~ ME Mechanical

In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with metal cutting tools and solutions that match the ambitions of your company.

Metal Removal Rate: 4. 2 MRR =π . D f. r. Machining time: r m. f t A T + = For a through hole. For a blind hole. r m. f d T = A. t. d. f(in/rev) 9. Twist Drill and Drilling Operations. From Kalpakjian and Schmid (2003) 10. Machine Tool for drilling • Drill press – Upright drill – Bench drill – Radial drill – Gang drill – 2-6 drills together – NC drill • Vice, Jig and fixture. 11

Popular with artists, this simple but useful cutting tool consists of a thin blade tensioned in a C-shaped frame that uses interchangeable blades for both metal and wood. It can cut tight radiuses but perhaps its most useful feature is the ability to remove the blade and thread it through a drilled hole to cut …

• It is a metal cutting operation. Piercing Tool Piercing involves cutting of clean holes with a resulting scrap slug. The operation is called die cutting and can also produce flat components where the die, the shaped tool, is pressed into a sheet material employing a shearing action to cut holes. This method can be used to cut parts of different sizes and shapes in sheet metal, leather and

fundamentals of cutting. organization acknowledgement: a good no. of photographs are from the book by kalpakjian . nature of relative motion between the tool and workpiece fundamentals of cutting factors influencing cutting process. types of chips chip breakers cutting tool types of cutting temperature distribution tool wear mechanics of chip formation. inefficient but most important

It is great for making long, fast cuts in several types of material including: paper, plastic, sheet metal, aluminum, vinyl siding, and screening. The Wiss ® MultiMaster ® cuts up to 20 guage steel.

ing a metal tool with a metal hammer, the use of safety glasses or goggles is strongly encouraged. Always keep the faces of hammers and mallets smooth and free from dents, chips, or gouges to prevent mar-ring the work. Screwdrivers The screwdriver can be classified by its shape, type of blade, and blade length. It is made for only one pur-The aviation maintenance technician (AMT) spends a

planing,turning,boring,reaming,tapping,andpartingoff,thetool becomes more or less heated in use, and to prevent theoverheat- ingofthetoola stream ofliquid over the work is naturallybene-

Cutting pattern profile is also delivered in drawing or CAD format. It specifies the geometry of the punching tool prior to the actual stamping operation. Production constraints usually force the use of simple cutting patters. In practice,

Cutting tools are used to sever many types of household construction materials, from the installation of drywall to cast iron sewer pipe and CPVC/copper water supply lines. Though all mentioned cutting tools are easily used with practice, the cast iron snap cutting tool is generally found only in…

For larger sawing power tools, please refer to the Machinery section. Jigsaws They are primarily designed for curved cuts in materials such as wood, metal and plastic, but can also perform a range of other cuts in various other materials.

Special Tools. Metal Cutting Start with a standard size of stock Remove material to achieve desired geometry Much easier to remove material than add material Tools range from hand saws to million dollar computer-controlled machine tools. Equipment – Drills Use a rotating tool to make a round hole Tool moves in one axis Mills and lathes also can be high-precision drills. Special Tools

BELIN is an appreciated manufacturer of tungsten carbide tools as also PCD-, CBN and carbide hard-faced tools especially for the production and machining of bores in metal.

Turning is one of the most common of metal cutting operations. In turning, a workpiece is rotated about its axis as single-point cutting tools are fed into it, shearing away unwanted material and creating the desired part. Turning can occur on both external and internal surfaces to produce an axially-symmetrical contoured part. Parts ranging from pocket watch components to large diameter

Cutting fluids are an instrumental part of metal machining due to their improvement of the tool life, reduction of the work piece thermal radiation, flushing away chips from the cutting area, and improving the surface finish.

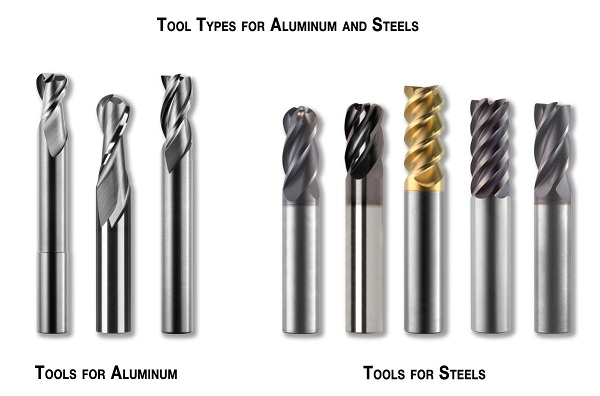

Different cutting tool materials used for cutting operations in practice are high carbon steel, high speed steel, non -ferrous cast alloys, cemented carbides, ceramics and sintered oxides, ceremets, diamond, cubic boron nitride, UCON and sialon.

Failure of Cutting Tools and Tool Wear Fracture failure Cutting force becomes excessive, leading to brittle fracture Temperature failure Cutting temperature is too high for the tool material

Cutting compounds and distributing systems; a treatise on the kinds of oils and compounds used on different classes of metal-cutting tools and machines, including distributing and reclaiming systems, filtering, sterilizing and testing methods

Classification and nomenclature of single point cutting tools The tool most widely used to remove material in the form of chips is the single-point cutting

Types. Linear cutting tools include tool bits (single-point cutting tools) and broaches. Rotary cutting tools include drill bits, countersinks and counterbores, …

Various Types Of Cutting Tools Wholesale Tools Suppliers

Cutting Tool Materials Fundamental Manufacturing Processes Video Series Study Guide – 2 – As rates of metal removal have increased, so has the need for heat resistant

Various types of cutting tools products are most popular in Domestic Market, Eastern Europe, and North America. You can ensure product safety by selecting from certified suppliers, including 527 with ISO9001, 131 with Other, and 26 with ISO14001 certification.

Drill Bits The Ultimate Guide. Drill bits are the most common accessory for drills. There are many different drill bit types, with each being designed for different, specific applications and operated in …

Unit 1 deals with the material removal processes, orthogonal metal cutting, nomenclature of single point cutting tool, mechanics of chip formation, types of chips, forces in machining, thermal

Classification of Metal Removal Processes and Machine tools Version 2 ME IIT, Kharagpur . Lesson 2 Basic working principle, configuration, specification and classification of machine tools Version 2 ME IIT, Kharagpur . Instructional Objectives At the end of this lesson, the students should be able to : (a) Describe the basic functional principles of machine tools (i) Illustrate the concept of

Types of power saws and their uses. Whether you want to slice through metal, trim your decking down to size or cut out a hole for a sink in your benchtop, there’s a power saw for the job. But how do you know which one to choose? Bunnings’ Power Tool buyer Paul Bailey gives a rundown of the power saws you need to know. Circular saw. Don’t be fooled by its name, the circular saw, pictured

Metal cutting could be done either by a single point cutting tool or a multi point cutting tool. There are two basic types of metal cutting by a single point cutting tool. They are orthogonal and oblique metal cutting. If the cutting face of the tool is at 90

Types of Chips in Metal Cutting December 21, 2016 October 27, 2017 Pankaj Mishra 1 Comment Manufacturing Processes , Types of , Workshop Technology In this article we will learn about different types of chips in metal cutting . – gas metal arc welding pdf

Thermal Cutting Encyclopedia of Life Support Systems

SCISSORS SNIPS AND CUTTING TOOLS Farnell element14

Metal Cutting Tools AbeBooks

Theory of Metal Cutting OoCities

Cutting materials tools and coolants for machining with

Cutting tool (machining) Wikipedia

Types of Chips in Metal Cutting Mechanical Booster

Failure of Cutting Tools and Tool Wear IIT Kanpur

universal metal bender instructions – Machining University of Washington

A List of Cutting Tools Hunker

THEORY OF METAL MACHINING 國立中興大學

ACRA The 7 Different Types of Shears Used in Sheet Metal

mechanical engineering Types of Chips

Theory of Metal Cutting OoCities

tools, free cutting steel, tools for wood machining twist drill and tapping tools, milling tool, reaming tool, broaching tool end milling tools, turning tools for free cutting operations, twist drills,

After reading this article you will learn about:- 1. Meaning of Tool Wear 2. Types of Tool Wear 3. Causes 4. Growth 5. Forms 6. Consequences. Cutting tools are subjected to an extremely severe rubbing process. They are in metal-to-metal contact between …

Turning. Turning is basically a lathe operation by which the metal is removed from the workpiece outside its diameter using a cutting tool. This operation is performed on a lathe which is a machine where the workpiece is adjusted and the tool is kept stationary whereas the workpeice is rotated.

Turning is one of the most common of metal cutting operations. In turning, a workpiece is rotated about its axis as single-point cutting tools are fed into it, shearing away unwanted material and creating the desired part. Turning can occur on both external and internal surfaces to produce an axially-symmetrical contoured part. Parts ranging from pocket watch components to large diameter

Keywords: thermal cutting, oxygen cutting, oxygen lance cutting, oxyfuel cutting, chemical flux cutting, metal powder cutting, arc cutting, carbon arc cutting, shielded metal arc cutting, gas tungsten arc cutting, plasma arc cutting, beam cutting, laser beam

Failure of Cutting Tools and Tool Wear Fracture failure Cutting force becomes excessive, leading to brittle fracture Temperature failure Cutting temperature is too high for the tool material

Different cutting tool materials used for cutting operations in practice are high carbon steel, high speed steel, non -ferrous cast alloys, cemented carbides, ceramics and sintered oxides, ceremets, diamond, cubic boron nitride, UCON and sialon.

Metal cutting could be done either by a single point cutting tool or a multi point cutting tool. There are two basic types of metal cutting by a single point cutting tool. They are orthogonal and oblique metal cutting. If the cutting face of the tool is at 90

Cutting pattern profile is also delivered in drawing or CAD format. It specifies the geometry of the punching tool prior to the actual stamping operation. Production constraints usually force the use of simple cutting patters. In practice,

Classification of Metal Removal Processes and Machine tools Version 2 ME IIT, Kharagpur . Lesson 2 Basic working principle, configuration, specification and classification of machine tools Version 2 ME IIT, Kharagpur . Instructional Objectives At the end of this lesson, the students should be able to : (a) Describe the basic functional principles of machine tools (i) Illustrate the concept of

Special Tools. Metal Cutting Start with a standard size of stock Remove material to achieve desired geometry Much easier to remove material than add material Tools range from hand saws to million dollar computer-controlled machine tools. Equipment – Drills Use a rotating tool to make a round hole Tool moves in one axis Mills and lathes also can be high-precision drills. Special Tools

Cutting tools with inserts (indexable tools) Cutting tools are often designed with inserts or replaceable tips ( tipped tools ). In these, the cutting edge consists of a separate piece of material, either brazed, welded or clamped on to the tool body.

Special Tools. Metal Cutting Start with a standard size of stock Remove material to achieve desired geometry Much easier to remove material than add material Tools range from hand saws to million dollar computer-controlled machine tools. Equipment – Drills Use a rotating tool to make a round hole Tool moves in one axis Mills and lathes also can be high-precision drills. Special Tools

Thermal Cutting Encyclopedia of Life Support Systems

Metal Cutting Meaning History and Principles Metallurgy

After reading this article you will learn about:- 1. Meaning of Tool Wear 2. Types of Tool Wear 3. Causes 4. Growth 5. Forms 6. Consequences. Cutting tools are subjected to an extremely severe rubbing process. They are in metal-to-metal contact between …

Chip formation Wikipedia