Sheet metal forming processes and applications pdf

Sheet metal forming processes and applications pdf

Sheet Metal Cutting & Forming Processes-General-The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. Therefore the first step in any sheet metal process is to cut the correct shape and sized ‘blank’from larger sheet. 2 3 Sheet Metal Cutting & Forming Processes-General

During try-out, sheet metal parts are checked for shape and dimensional accuracy as well as for material defects: part geometry, springback, trimming, hole pattern, material thickness and forming limit analysis. For the series-accompanying quality control, measuring and evaluation processes …

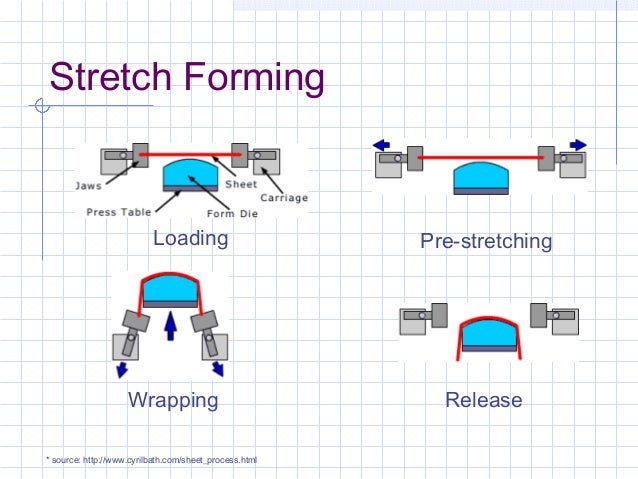

sheet metal forming. Attendees will learn about basic forming applications such as Attendees will learn about basic forming applications such as blanking, bending, flanging, and deep drawing, as well as more advanced forming

White Paper: Vacuum Forming Applications Using PolyJet™ Rapid Prototyping Technology Page 2/3 . a knife is used to score the perimeter. a more sophisticated machine is necessary to heat both the frame’s surface and the mold. The mold is an Objet 3D printed model. Heaters move into position both above and below the sheet. For thicker sheets. sophisticated machines possessing a variety of fine

Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters. Other chapters cover sensors and die materials, which are critical for practical sheet forming applications. Other topics include relatively new technologies, such as

9.2,Material,in,sheet,metal,forming,processes:,.Sheet,,,Metal,,,Work,,,employed,,,by,,,them,,,dur,,,ing,,,their,,,many,,,Adolf,,,Hopp,,,Estimating,,,sheet,,,metal

Sheet Metal Forming Processes And Applications. These files are related to sheet metal forming processes and applications. Just preview or download the desired file.

Sheet-Metal Forming Processes Process Characteristics Roll forming Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs.

Sheet Metal Forming Processes and Applications by Edited

APPLICATION OF INCREMENTAL SHEET FORMING MPER

Sheet Metal Forming – Processes and Applications Details This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling.

ADVANCES IN SHEET METAL FORMING TECHNOLOGIES In the article the changes associated with construction of machines used in die and die-less sheet metal forming have been presented. The selected future directions of development in new technologies and machines for sheet metal forming taking into account modern blank holding systems in the process of deep drawing have been …

PREFACE A very large variety of sheet-metal forming processes is used in modern sheet-metal press-working shop practice. Many of these deformation processes, used in making aircraft, automobiles, and other products, use complex equipment that is derived from the latest discoveries in science and technology. With the everincreasing knowledge of science and technology, future …

21/11/2016 · Watch video · By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design – still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. It illustrates several different approaches to this intricate field by taking the …

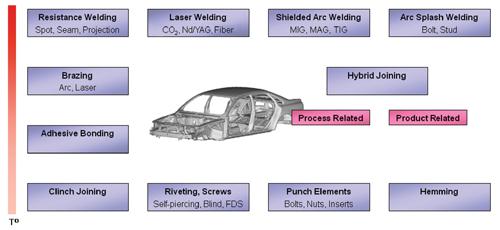

ProSheet Prototyping and low volume production of sheet metal components 5 2.2. Multi-process equipment Most sheet metal products are subject to additional processing to the forming operation.

Fundamentals of Metal Forming Outline 9Mechanical Properties – Example 9Overview of Metal Forming 9Cold working – Strain Hardening 9Annealing – Recrystallization 9Temperature in Metal Forming 9Friction and Lubrication in Metal Forming Dr. M. Medraj Mech 421/6511 lecture 3/2 Example A metal obeys the Hollomon relationship and has a UTS of 300 MPa. To reach maximum load …

Sheet metal forming processes have been classified into conventional and unconventional forming processes. The main difference between conventional and unconventional forming is the type of tools used in the process. In a conventional

Sheet Metal Forming: Processes and Applications Edited by Taylan Altan and Erman Tekkaya 2012 Approx. 400 pages This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process

7/01/2016 · Why Forming JC When Suspects Have Admitted To Crime,Reham Khan-Geo Reports-10 Aug 2015

adding continuous fiber reinforced composites or sheet metal, the possible range of applications can be greatly increased while retaining the advantages of the molding processes, cost efficiency and …

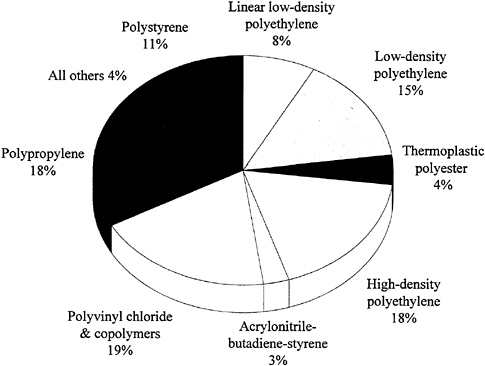

9.2 Material in sheet metal forming processes: Low-carbon steel is the most commonly used sheet metal because of its low cost and generally good strength and formability characteristics. Aluminum is the most common material for such sheet-metal applications as beverage cans, packaging, kitchen utensils, and applications where corrosion resistance is a concern. The common metallic materials …

His research interests include computer aided sheet metal die design, AI applications to sheet metal forming, CAD/CAM, AutoCAD application and customization, and CAPP. He has completed many research projects in the area of design and manufacturing sanctioned by various funding agencies. He is a member of the Egyptian Syndicate of Professional Engineers, and of the Egyptian Mechanical …

ManagementandProductionEngineeringReview Application The described mould incremental sheet forming process has been used for making the skull prosthesis

Application Example: Sheet Metal Forming Modern measuring tools in stamping applications for complex and simple parts Measuring Systems: ARGUS Keywords: Tool optimization ARGUS measures and visualizes the quality and degree of the stamping process on sheet metal. For the ARGUS measurement of a simple stamped sheet metal part, only few images are taken, but ARGUS also …

Sheet Metal Forming PROCESSES AND APPLICATIONS Edited by Taylan Altan and A. Erman Tekkaya ASM International® Materials Park, Ohio 44073-0002 www.asminternational.org

This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more.

By Edited by Taylan Altan and Erman Tekkaya. ISBN-10: 1615038442. ISBN-13: 9781615038442. This sensible and complete reference provides the newest advancements at the layout of sheet forming operations, gear, tooling, and approach modeling. person chapters disguise all significant sheet forming methods equivalent to blanking, bending, deep

Butterworth-Heinemann, 2002, 211 pages, ISBN 0 7506 5300 0 In this book, the theory of engineering plasticity is applied to the elements of common sheet metal forming processes.

A sheet metal forming process and apparatus using both a mechanical forming step and a superplastic forming step. The mechanical forming step includes using a …

[PDF Download] Sheet Metal Forming Processes and

Applications of Finite Element Simulation in the Development of Advanced Sheet Metal Forming Processes Sandip Jadhav, Martin Schoiswohl, and Bruno Buchmayr Lehrstuhl für Umformtechnik, Montanuniversität Leoben, Loeben, Austria Received December 15, 2017; accepted January 21, 2018; published online February 5, 2018 Abstract: Sheet metal forming is widely used in automo-tive, …

1 Advances and Challenges in Sheet Metal Forming Technology T. Altan, A. Groseclose, E. Billur, S. Subramonian, T. Mao, Engineering Research Center for Net Shape Manufacturing (ERC/NSM), The Ohio State University, Columbus OH, USA.

Sheet metal has massive application worldwide and is a highly important form in most manufacturing sectors such as aerospace, automotive, food industry and across nearly all manufacturing industries. Forming process are both abundant and varied in their application and can include more common

Metal Spinning is the process of forming metal to a pattern on a manual or automatic lathe, using hand-held tools on manual lathes and computer controlled rollers on automatic lathes.

Of these manufacturing processes, forming is a widely used process which finds applications in automotive, aerospace, defense and other industries. Wrought forms of materials are produced through bulk or sheet forming operations.

Fundamentals and Applications of Sheet Metal Forming (1-Day Course) Applications of Sheet Metal Forming introduces various industrial applications of sheet metal forming. Attendees will learn about basic forming applications such as blanking, bending, flanging, and deep drawing, as well as more advanced forming applications like hot stamping, warm forming, sheet/tube hydroforming, …

Fundamental of metal forming processes. cot 1 1 . tan (6) The strain hardening of metal can be considered (in σ0 of (6)) by taking an average yield strength like ( 01 02) where σ01. C 1 ln( A 0 ) 2 ln R2 A 1 Put the value of ‘C’ in (5). R.

This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process modeling using finite element analysis is described in one chapter

The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal forming processes, and focus on the automation of those processes by means of AI techniques, such as KBS, ANN, GA, CBR, etc. Feature recognition and the manufacturability assessment of sheet metal parts, process

The flow stress O is important because in metal-forming processes the forming loads and stresses depend on (1) part geometry, (2) friction, and (3) the flow stress of the deforming material. – 1 1 2 manual metal hole punch Demonstrates applications of various AI techniques in sheet metal forming, using real industrial sheet metal parts Includes flow charts explaining the execution of the systems developed using AI techniques Presents research work that, if implemented in the sheet metal industry, could dramatically

[PDF] Online Sheet Metal Forming Processes and Die Design

Fundamentals of Metal Forming Example

Sheet-Metal Forming Processes academia.edu

SIMULATION OF COMBINED FORMING AND INJECTION MOLDING PROCESSES

ANALYSIS AND TECHNOLOGY IN METAL FORMING

Sheet metal forming processes and applications (eBook

Download AI Applications in Sheet Metal Forming SoftArchive

https://en.wikipedia.org/wiki/Forming_processes

Sheet Metal Forming Processes and Applications Google Books

– Sheet Metal Forming Processes and Applications Shape

Amazon.com Sheet Metal Forming Processes and

AI Applications in Sheet Metal Forming PDF Free Download

Sheet Metal Forming Processes And Applications Pdf Download

Sheet Metal Forming: Processes and Applications Edited by Taylan Altan and Erman Tekkaya 2012 Approx. 400 pages This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process

Sheet Metal Forming Processes and Applications Google Books

AI Applications in Sheet Metal Forming PDF Free Download

[PDF] Online Sheet Metal Forming Processes and Die Design