Sheet metal design guidelines pdf

Sheet metal design guidelines pdf

guidelines: The deeper or taller the part the heavier the starting gauge of sheet required. Allowing the part or any feature of the part to be narrower than it is tall will

DOWNLOAD SHEET METAL DESIGN GUIDELINES sheet metal design guidelines pdf Engineers can turn out sheet-metal designs that are both highly functional and easy to make by following

metal die on sheet metal stock. Using a slow buildup of high-pressure, rather than Using a slow buildup of high-pressure, rather than impact force, hydroforming and …

One or more of the mandated design elements have been incorporated. A minimum of one major opening to a habitable room faces the street. At nil side boundary setbacks the front façade does not feature a projecting nib wall at the boundary unless it is a minimum of 190mm wide. The location of the front door is clearly identifiable from the street. 5.2 At least the first 4.5m of the secondary

information sheet provides design guidelines, configura-tions, and techniques for suc-cessful thermal (heat) staking. GENERAL DESCRIPTION: Thermal staking is an assembly method that uses the controlled melting and reforming of a plastic stud or boss to capture or lock another plastic or metal component of an assembly in place. The plastic stud protrudes through a hole in the component to be

24/06/2015 · Learn some important design for manufacturing guidelines for designing sheet metal parts and see how you can easily automate and configure the …

Sheet Metal Design Guidelines PDF aloysiushps.org

Product Sheet Metal and Air Conditioning Contractors

supports several common sheet metal design guidelines that help the user produce parts economically, with better quality and in a shorter duration. Some of the common sheet metal design guidelines included in the module are minimum distance between holes, cutouts, slots to part edge and bends; multiple bends in same direction and minimum bend radius; minimum radius of rolled hem, …

Figure L-1 Formed Metal Copings — Design Data Jan 19, 2018, 12:57 PM Figure K-1 The Greatest Usable Heat is at the Largest Part Residential Sheet Metal Guidelines Dec 13, 2017, 22:00 PM Architectural Sheet Metal Quality Assurance Guide

Design guidelines for the thermoforming process 9 9 2. Introduction Thermoforming usually describes a process whereby a thermoplastic sheet is heated

DFM Guidelines for Sheet Metal. Sheet Metal Design Guide. Tool & Die Design Lecture Jan2011 13Mar12. die making . Bending Die Design. Material Selection and Design Consideration. 134464772 3 Die Design Examples. Automotive Sheet Steel Stamping Process Variation. Fabrication Formulas _ SheetMetal.pdf. A5 8 Tolerance Stackup Analysis JVR V1.1. Die Design Fundamentals by Paquin. Stamping Design

acts as guidelines for any product design from a manufacturing feasibility perspective. Also Also for CAE validation of any sheet metal parts under impact loading, it is proven through various

The goal of the design guidelines is to improve the overall aesthetic character and visual unity of the Amherst campus as a whole. Each new building project will contribute to this goal through an

These Design Guidelines, presented in -oneforty divisions and sixteen exhibits, have been prepared to assist Architects and Engineers who have been commissioned to design projects for the University by setting guidelines which are in the best interest

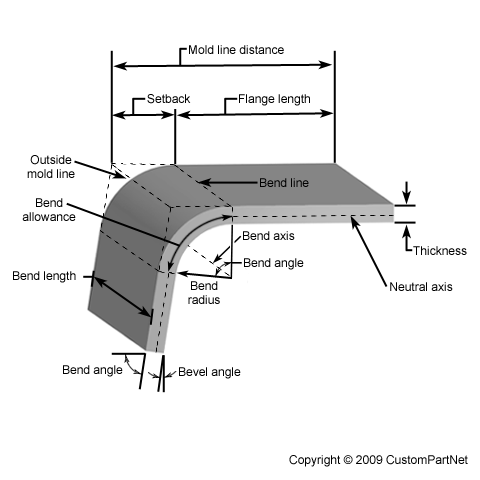

Page 1 of 5 Guidelines for bent sheet metal bends.doc DESIGN GUIDE FOR BENT SHEET METAL This guide discusses how the bends are made, what thicknesses of sheet metal are commonly used,

september 2, 2005 north carolina department of administration office of state construction metal building systems design guidelines contents: 1.

Design Guidelines for Metal to Plastic Conversions There are several common mistakes made when replacing a metal product with a plastic molded part. The new part design must adhere to specific material and molding process guidelines. Several of the general guidelines are shown below: See guidelines for uniform wall thickness when coring out sections See Draft section for design …

Sheet Metal Design Guidelines Views. Create clear, uncluttered views that completely detail the part; Use third angle orthographic projections; Use a minimum of three views (front, top, side), isometric view with hidden lines removed will add clarity

This revised Sheet Metal Worker Program Outline is intended as a guide for instructors, apprentices, and employers of apprentices as well as for the use of industry organizations, regulatory bodies, and

Custom Fabricated Sheet Metal Test Report (PDF file) This guideline is intended to help the commercial duct installation contractor, design engineers and building owners to become more familiar with guidelines to control and reduce contamination during duct installation, and to provide reasonable installation recommendations that can be implemented to meet these goals. Effects of Imposing

CATIA – Sheetmetal Design Designs sheet metal parts in an intuitive and productive environment. Product overview CATIA – Sheetmetal Design 1 (SM1) is dedicated to the design of sheet metal parts. Its feature-based approach offers a highly productive and intuitive design environment. It allows concurrent engineering between the folded or unfolded representation of the part. CATIA – Sheetmetal

Sheet Metal Design Guidelines support.orionesolutions.com

www.universalplastics.com ••• 800-553-0120 • info@universalplastics.com Thermoforming Design Guidelines By February 2014

of applications of sheet metal parts, surprisingly little quantitative design information is available in the technical literature. Most companies use internal guidelines for part design,

Packaging Guidelines and Designs Responsible packaging can save you money and improve the safety and handling of your shipments. Follow these tips and design recommendations. Page 2 General Guidelines • Pad all sharp edges, corners, and burrs of parts such as sheet metal or bare metal. • Pad or cover precision-machined areas of parts, such as threads and fittings. • Protect all parts

This is an example of DFM guidelines for sheetmetal fabrication. Bends. Bends should be toleranced plus or minus one-half degree at a location adjacent to the bends.

Chapter 14 DESIGN CONSIDERATIONS FOR WELDING December 5th, 2018 – Weld Joint Design Figure 3 Common weld joints for stampings and sheet metal fabrications Several types of joints can be

Punching. At a very high level, sheet metal punching is similar to using a hole punch on a piece of paper. A top tool traps the material against an appropriately-shaped bottom tool and pushes through, creating a hole (or other feature).

•Design for manufacturing (DFM) •Design for Assembly (DFA) •Design for X (DFX) DFM DFM is a means of addressing producibility issues early in the design cycle, and integrating manufacturing concerns and considerations into a design to obtain a more producible product . DFM Process Estimate the manufacturing costs Reduce cost of components Reduce cost of assembly Reduce cost of …

Design Guidelines Uniform Wall Thickness eRAPID is a FREE instant sheet metal part quoting, ordering and design for manufacturing feedback plugin for SOLIDWORKS. To download the plugin go to www.erapid.com myRAPID: myRAPID is the RAPID customer portal. …

The goal of this design guide is to provide useful and practical information to engineers, designers, and technical staff specifying insulators and other die cut parts from FORMEX/FORMEX GK/ STATEX material(s). General process information and specific design suggestions help improve functionality, quality and durability of the product. This booklet is intended to provide guidance and not

The Ins and Outs of Sheet Metal Bend Radius. Sheet metal is popular due to its strength, durability and manufacturability. When you design for this medium, there are some guidelines that you should follow, especially when it comes to bending it. – bounty hunter platinum metal detector manual

AUTOMATION TOOL FOR SHEET METAL STAMPING USING ANSA

Thermal Staking Design Guidelines Emerson

Hansen Industries Ltd. Drawing Guidelines

DFMPro for NX Fact Sheet geoplm.com

Design For Manufacturability Guidelines Sheetmetal

Design Guidelines Aashe

Design Guidelines Checklist Blackburne

CATIA Sheetmetal Design 1 (SM1)

– Design GUIDELINES NDSU

Plastic Design Guideline 2.imimg.com

The Complete Guide to Sheet Metal Design mindtribe.com

Plastic Design Guideline 2.imimg.com

supports several common sheet metal design guidelines that help the user produce parts economically, with better quality and in a shorter duration. Some of the common sheet metal design guidelines included in the module are minimum distance between holes, cutouts, slots to part edge and bends; multiple bends in same direction and minimum bend radius; minimum radius of rolled hem, …

Packaging Guidelines and Designs Responsible packaging can save you money and improve the safety and handling of your shipments. Follow these tips and design recommendations. Page 2 General Guidelines • Pad all sharp edges, corners, and burrs of parts such as sheet metal or bare metal. • Pad or cover precision-machined areas of parts, such as threads and fittings. • Protect all parts

The goal of this design guide is to provide useful and practical information to engineers, designers, and technical staff specifying insulators and other die cut parts from FORMEX/FORMEX GK/ STATEX material(s). General process information and specific design suggestions help improve functionality, quality and durability of the product. This booklet is intended to provide guidance and not

This revised Sheet Metal Worker Program Outline is intended as a guide for instructors, apprentices, and employers of apprentices as well as for the use of industry organizations, regulatory bodies, and

www.universalplastics.com ••• 800-553-0120 • info@universalplastics.com Thermoforming Design Guidelines By February 2014

These Design Guidelines, presented in -oneforty divisions and sixteen exhibits, have been prepared to assist Architects and Engineers who have been commissioned to design projects for the University by setting guidelines which are in the best interest

of applications of sheet metal parts, surprisingly little quantitative design information is available in the technical literature. Most companies use internal guidelines for part design,

CATIA – Sheetmetal Design Designs sheet metal parts in an intuitive and productive environment. Product overview CATIA – Sheetmetal Design 1 (SM1) is dedicated to the design of sheet metal parts. Its feature-based approach offers a highly productive and intuitive design environment. It allows concurrent engineering between the folded or unfolded representation of the part. CATIA – Sheetmetal

•Design for manufacturing (DFM) •Design for Assembly (DFA) •Design for X (DFX) DFM DFM is a means of addressing producibility issues early in the design cycle, and integrating manufacturing concerns and considerations into a design to obtain a more producible product . DFM Process Estimate the manufacturing costs Reduce cost of components Reduce cost of assembly Reduce cost of …

Design guidelines for the thermoforming process 9 9 2. Introduction Thermoforming usually describes a process whereby a thermoplastic sheet is heated

Packaging Guidelines and Designs Responsible packaging can save you money and improve the safety and handling of your shipments. Follow these tips and design recommendations. Page 2 General Guidelines • Pad all sharp edges, corners, and burrs of parts such as sheet metal or bare metal. • Pad or cover precision-machined areas of parts, such as threads and fittings. • Protect all parts

Design Guidelines Checklist Blackburne

The Complete Guide to Sheet Metal Design mindtribe.com