Sheet metal design considerations pdf

Sheet metal design considerations pdf

Plastic Component Design Considerations Design Guidelines for Metal to Plastic Conversions There are several common mistakes made when replacing a metal product with a plastic molded part. The new part design must adhere to specific material and molding process guidelines. Several of the general guidelines are shown below: See guidelines for uniform wall thickness when coring out sections See

Design Rule Chec k er for Sheet Metal Comp onen ts using Medial Axis T ransforms and Geometric Reasoning Ra j Radhakrishnan, Ara y a Amsalu, Mehran Kamran and B.O. Nna ji

After a detailed description of the recent developments of sheet metal technology, the main characteristics of sheet metal and the new types of sheet used …

Sheetmetal design Consideration – Free download as PDF File (.pdf), Text File (.txt) or read online for free. sheet metal tolerances and their part design consideration Search Search

sheet metal working and machine tool exhibitions Special report The latest development in 1D-3D CFD simulation software. technology technology 30 Hemming Hemming 31 A s long as car body panels – specifically closures such as boot and hood lids – are made out of metal they are likely to continue to be subject to hemming as a means of joining different panels together. The basic technique is

In addition to these considerations, using the following guidelines will increase the manufacturability of designs for press brake forming. Dimension the part in a single direction wherever possible.

Metal selection. Major considerations for the metal selection are the types of metal and their thickness. Protocase’s standard offerings include carbon steel (cold rolled steel or galvanneal), stainless steel, aluminum, and copper.

Sheet metal design plays a vital role in the making of a strong backbone. A designer must have a clear set of goals and design strategies established to ensure that part design is cost effective and can be easily manufactured.

DESIGN FOR ASSEMBLY NPTEL

Selection Design Considerations and Details rlcraigco.com

Sheet Metal Design Handbook. 08 – Sheet Metal Work. Sheet Metal Guide (Mate) Sheet Metal Design Guideline 98053007 30006. Sheet Metal Best Practices. Sheet Metal. sheet metal design. 06 Sheet-Metal Forming 2. Sheet Metal Design1. Press Tool Calculation. Sheet matel calculations. Sheet Metal Design_guide. DFM Guidelines for Sheet Metal. Tool & Die Design Lecture Jan2011 13Mar12. Sheet Metal

Sheet metal design. These three simple words can have a tremendous impact on a company’s bottom line. Ideally, effective, innovative, and creative sheet metal design ideas come early in the product design phase, because those ideas will influence the entire project, from the point of manufacturing to the product’s end use.

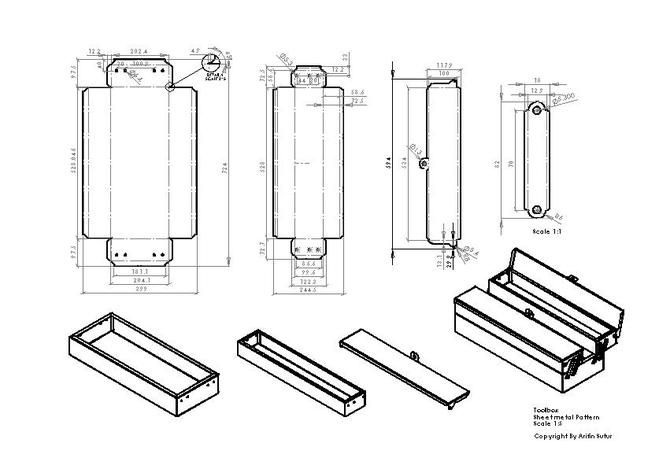

The study investigates the application of flat pattern tools for sheet metal products derived from analysis for thin or zero thickness sheets (i.e. paper origami). The analysis sets an approach to generate all possible configurations of flat patterns that result in a specific 3-D structure profile. Secondly, a set of optimality selection metrics are developed and applied to these

Designing sheet-metal parts as 3D solid models sounds odd. The parts are punched, stamped, or burned out of flat material that’s easy to describe in 2D CAD.

Figure 6 Final design: sheet metal transfer apparatus The boom is composed of two Hbeams secured together and guided by a system of three trolleys, custom designed to travel along the beams.

neglect to teach sheet metal design for manufacturability altogether. This knowledge gap has created consequences for even the largest of manufacturers, because the engineered components are too costly to successfully enter production. Filling the Knowledge Gap Maysteel’s Technical Design Center, referred to as its Tech Center, was established in 1994 specifically to help customers mitigate

Design considerations of flat patterns analysis techniques when applied for folding 3-D sheet metal geometries

Homemade sheet metal semi auto pistol drawings. For academic study purposes only. Free book, no copyright. For academic study purposes only. Free book, no copyright.

Sheet Metal Design Services Sheet Metal Design Considerations Tolerances The punched feature-to-feature tolerance for Sheetmetal parts is +/-0.1mm, with a general folding tolerance of +/0.25mm

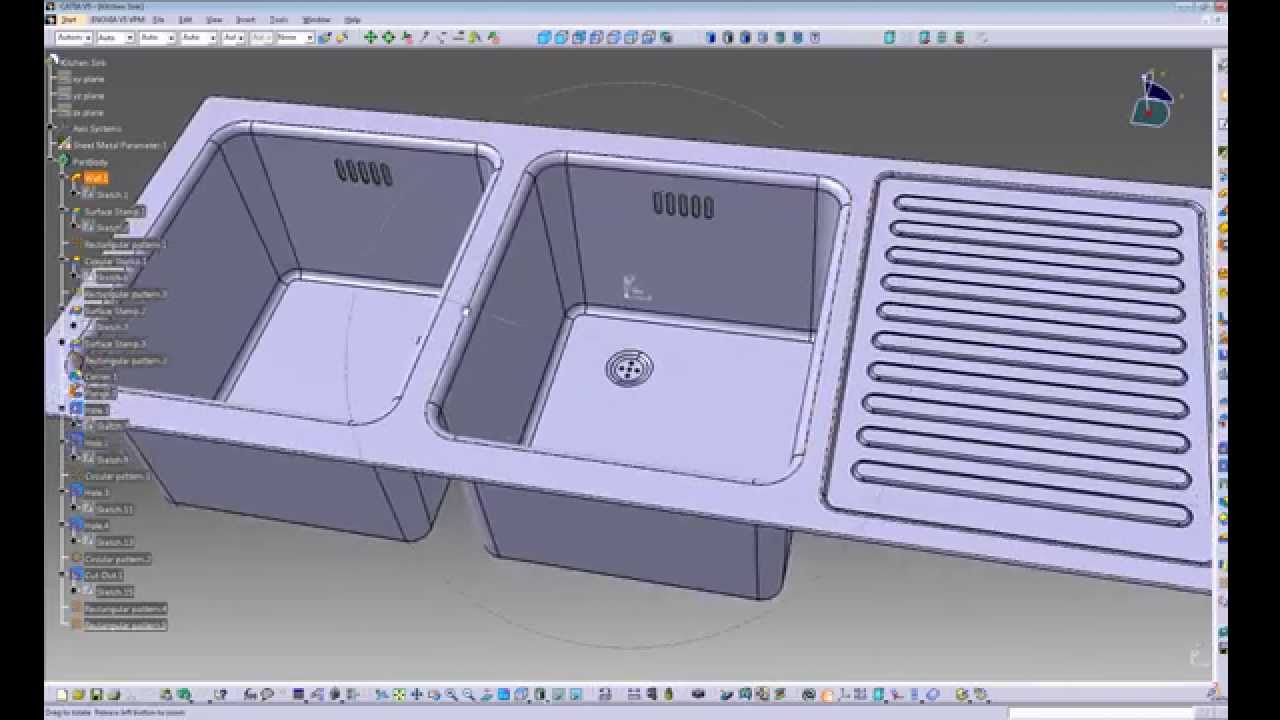

Download PDF. Recommend Documents. Sheet Metal Design – CATIA – CATIA Strona główna . Using This Product This guide is intended for the user who needs to become quickly familiar with the CATIA – Sheet Metal Design Version€5 product . Cooling & Sheet Metal . 3 The following section, Apprentice Responsibilities, is taken from the State of Connecticut-Apprentice Handbook & Progress Report

Advanced sheet metal Advanced Sheet Metal Design tools are also available to aid in the design of complex sheet metal parts. NX. Also included is a new method to generate sheet metal parts from a solid which allows users to quickly design a sheet metal enclosure around it • Robust flat pattern and capabilities for sheet metal validation. which aid in manufacturing processes With a reduced

DESIGN FOR ASSEMBLY Assembly is an important stage in product development and accounts for one third of the company labor. Reducing the number of …

the sheet metal (the amount of force that will cause Figure 2-7. A shear stress on a rivet attempts to slide through the rivet shank. RIVET JOINT CONSIDERATIONS The design of an aircraft repair is complicated by the requirement that it be as lightweight as possible. If weight were not critical, all repairs could be made with a large margin of safety so there would never be a concern about the

called sheet metal workers. In fact, sheet metal use in HVAC is greater than all other materials In fact, sheet metal use in HVAC is greater than all other materials combined.

R.L. Craig Company, Inc. 502-244-1600 Serving the HVAC Industry Since 1955 Louvers Selection, Design Considerations and Details Written by Matt Trentham, R.L. Craig Company, Inc.

Sheet metal design guide for designing precision sheet metal components and making the best use of laser cutting and folding techniques. These pages explain sheet metal design considerations in more detail. Subcontract metal component supplier Hydram Sheet Metalwork.

Sheet Metal Design Considerations – Download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online. sheet metal design considerations

Rapid Sheet Metal Overview eRAPID is a FREE instant sheet metal part quoting, ordering and design for manufacturing feedback plugin for SOLIDWORKS. To download the plugin go to www.erapid.com myRAPID: myRAPID is the RAPID customer portal. …

(PDF) Design considerations of flat patterns analysis

We manufacture custom sheet metal electronic enclosures, mounting hardware, and miscellaneous components. We start from your design, and build them in 2-3 days, with no minimum order requirements. Extra lead time may be required for use of non-stocked components or materials, large quantity orders or for silkscreening (due to drying time). If time is critical for your job, be sure to …

Sheet metal parts are frequently designed without the systematic consideration of product development requirements like manufacturability, process planning, manufacturing optimization and production planning. Concurrent Product Design and Manufacturing means that the designer has to consider all the

Design considerations prior to sarking selection For roof sarking to be effective below metal roofing, the selection of the appropriate type of sarking material must be made with due consideration to condensation risk which can be influenced by the following:

Introduction Page 1 This manual is intended as a practical guide for automotive material engineers, product designers and die process planners when using high strength steels for …

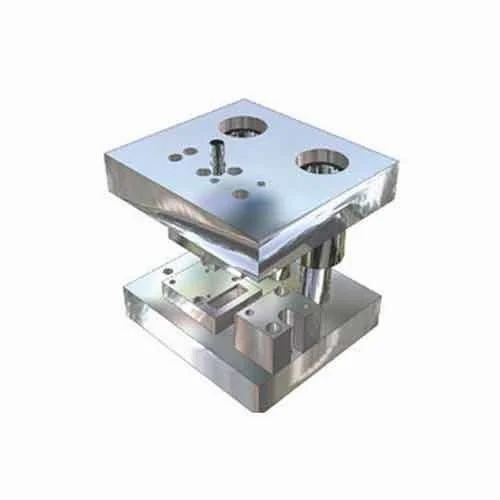

Metal Stamping and Design Considerations, Part 2: Forming. A progressive die can control an inside radius but cannot control an outside radius. Similarly, the die can control dimensions to the inside of a bend but not to the outside.

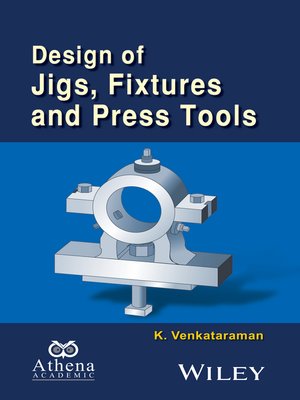

Design considerations in bending sheet metal –minimum bend radius, bending with respect to the direction of rolling, minimum flange widths, hole spacings etc.

g India Business Center Design For Manufacturability Sheet Metal Part Design By Suresh Sunnam 2. g India Business Center Table of contents Process details : •Types of sheet metal operations •Press working principles Tool details : •Types of press tools •Types of Press Machines •Guidelines : •Part design considerations.

Rapid Sheet Metal is an industry leader in custom sheet metal prototype parts. The 5-day turbo service is used when prototype sheet metal parts do not require custom bend radii, documentation such as first article inspection, and material certifications. – cisc steel fabrication quality systems guideline Design Considerations in Metal Casting Mold and Gating System Design, Directional Solidification, and Troubleshooting In the previous sections we discussed the fundamental aspects of manufacturing parts by metal casting. We covered the creation of patterns, and the setup of the mold and gating system. Also we discussed the casting operation itself including the pouring of the molten material

f6a8-4c7c-8207-eb6510b27548&file=Sheet_Metal_Design_Considerations.pdf Part 2 shows a bend relief cut into the Sheet Metal Design Services Send versatile solutions for putting special features

2 offer a number of features that support the sheet metal design process. Software can help build up the geometry using a combination of sketches and intelligent features,

Metal Stamping and Design Considerations Part 2 Forming

Sarking metal roofs Bradford Insulation

Understanding sheet metal lynda.com

Sheet Metal Transfer Device web.cecs.pdx.edu

Design considerations of flat patterns analysis techniques

Frequently Asked Questions on Building Custom Enclosures

Bending Design Considerations eFunda

https://en.wikipedia.org/wiki/Expanded_sheet_metal

The DIY Sheet Metal Self-Loading Pistol.pdf PDF Free

– Design and Manufacturing Assistance Tool for Drawing Sheet

Sheet MeAUTODESK INVENTORtal Design Considerations

Design and Manufacturing Assistance Tool for Drawing Sheet

Sheet Metal Design Considerations – Download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online. sheet metal design considerations

Design considerations in bending sheet metal –minimum bend radius, bending with respect to the direction of rolling, minimum flange widths, hole spacings etc.

Sheet Metal Design Services Sheet Metal Design Considerations Tolerances The punched feature-to-feature tolerance for Sheetmetal parts is /-0.1mm, with a general folding tolerance of /0.25mm

Plastic Component Design Considerations Design Guidelines for Metal to Plastic Conversions There are several common mistakes made when replacing a metal product with a plastic molded part. The new part design must adhere to specific material and molding process guidelines. Several of the general guidelines are shown below: See guidelines for uniform wall thickness when coring out sections See

Advanced sheet metal Advanced Sheet Metal Design tools are also available to aid in the design of complex sheet metal parts. NX. Also included is a new method to generate sheet metal parts from a solid which allows users to quickly design a sheet metal enclosure around it • Robust flat pattern and capabilities for sheet metal validation. which aid in manufacturing processes With a reduced

Download PDF. Recommend Documents. Sheet Metal Design – CATIA – CATIA Strona główna . Using This Product This guide is intended for the user who needs to become quickly familiar with the CATIA – Sheet Metal Design Version€5 product . Cooling & Sheet Metal . 3 The following section, Apprentice Responsibilities, is taken from the State of Connecticut-Apprentice Handbook & Progress Report

Sheet metal design. These three simple words can have a tremendous impact on a company’s bottom line. Ideally, effective, innovative, and creative sheet metal design ideas come early in the product design phase, because those ideas will influence the entire project, from the point of manufacturing to the product’s end use.

Rapid Sheet Metal Overview eRAPID is a FREE instant sheet metal part quoting, ordering and design for manufacturing feedback plugin for SOLIDWORKS. To download the plugin go to www.erapid.com myRAPID: myRAPID is the RAPID customer portal. …

Homemade sheet metal semi auto pistol drawings. For academic study purposes only. Free book, no copyright. For academic study purposes only. Free book, no copyright.

the sheet metal (the amount of force that will cause Figure 2-7. A shear stress on a rivet attempts to slide through the rivet shank. RIVET JOINT CONSIDERATIONS The design of an aircraft repair is complicated by the requirement that it be as lightweight as possible. If weight were not critical, all repairs could be made with a large margin of safety so there would never be a concern about the

Sheet metal design plays a vital role in the making of a strong backbone. A designer must have a clear set of goals and design strategies established to ensure that part design is cost effective and can be easily manufactured.

Rapid Sheet Metal is an industry leader in custom sheet metal prototype parts. The 5-day turbo service is used when prototype sheet metal parts do not require custom bend radii, documentation such as first article inspection, and material certifications.

Sheetmetal design Consideration – Free download as PDF File (.pdf), Text File (.txt) or read online for free. sheet metal tolerances and their part design consideration Search Search

Design Rule Chec k er for Sheet Metal Comp onen ts using Medial Axis T ransforms and Geometric Reasoning Ra j Radhakrishnan, Ara y a Amsalu, Mehran Kamran and B.O. Nna ji

Design considerations prior to sarking selection For roof sarking to be effective below metal roofing, the selection of the appropriate type of sarking material must be made with due consideration to condensation risk which can be influenced by the following:

In addition to these considerations, using the following guidelines will increase the manufacturability of designs for press brake forming. Dimension the part in a single direction wherever possible.

Design considerations of flat patterns analysis techniques

Sheet+MeAUTODESK INVENTORtal+Design+Considerations