Metal inert gas welding pdf

Metal inert gas welding pdf

Come along to our MIG (metal inert gas) Welding course and learn professional techniques on steel. Learn how to use the GMAW (gas metal arc welding) process to manufacture and assemble your projects at home.

MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding. In this type of welding process, a shielded gas is used along the wire electrode, which heats up the two metals to be joined. A constant voltage and direct current power

Metal Inert Gas (MIG) / Metal Active Gas (MAG) welding refers to a group of arc welding processes that use the heat generated by a DC electric arc to fuse the metal in the joint area. A continuous electrode (the wire) is fed by powered feed rolls (wire feeder) into the weld pool.

Metal Inert Gas Welding which is also known as Gas Metal Arc Welding (GMAW) uses a consumable metal electrode and an inert gas or an active gas. It is the process in which source of heat is an arc formed between a consumable metal electrode and the work piece. The arc and molten puddle are protected from contamination by the atmosphere with an externally supplied gaseous shield of inert gas …

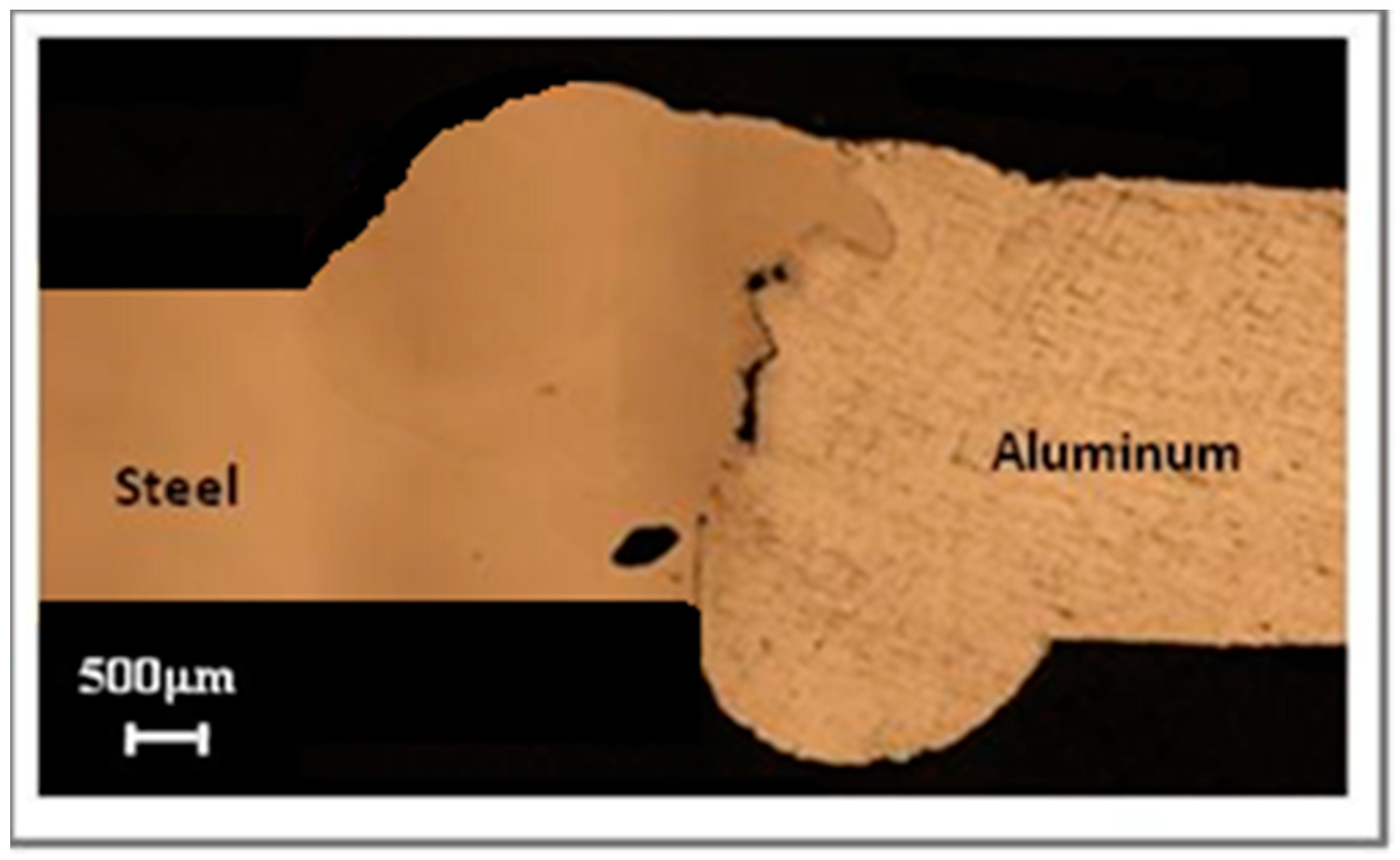

The present work is an experimental comparison between the friction stir welding (FSW) and the conventional gas metal arc welding (GMAW) in joining of Al alloys.

Abstract – Metal Inert Gas welding (MIG) process is an important welding operation for joining ferrous and non ferrous metals. The MIG input welding parameters are the most important factors affecting the quality of the welding and weld quality is strongly characterized by weld bead geometry. The optimization of parameters considering multiple performance characteristics of the Pulsed Current

As a replacement for the archaic stick welding method, MIG welding is without a doubt one of the most efficient welding forms in the industry, and it happens to be an acronym for Metal Inert Gas.

I n my adventure of building an all-aluminum Zenith 601XL kit, I have learned many new skills. Working with aluminum, as I expected, is where I spend most of my time.

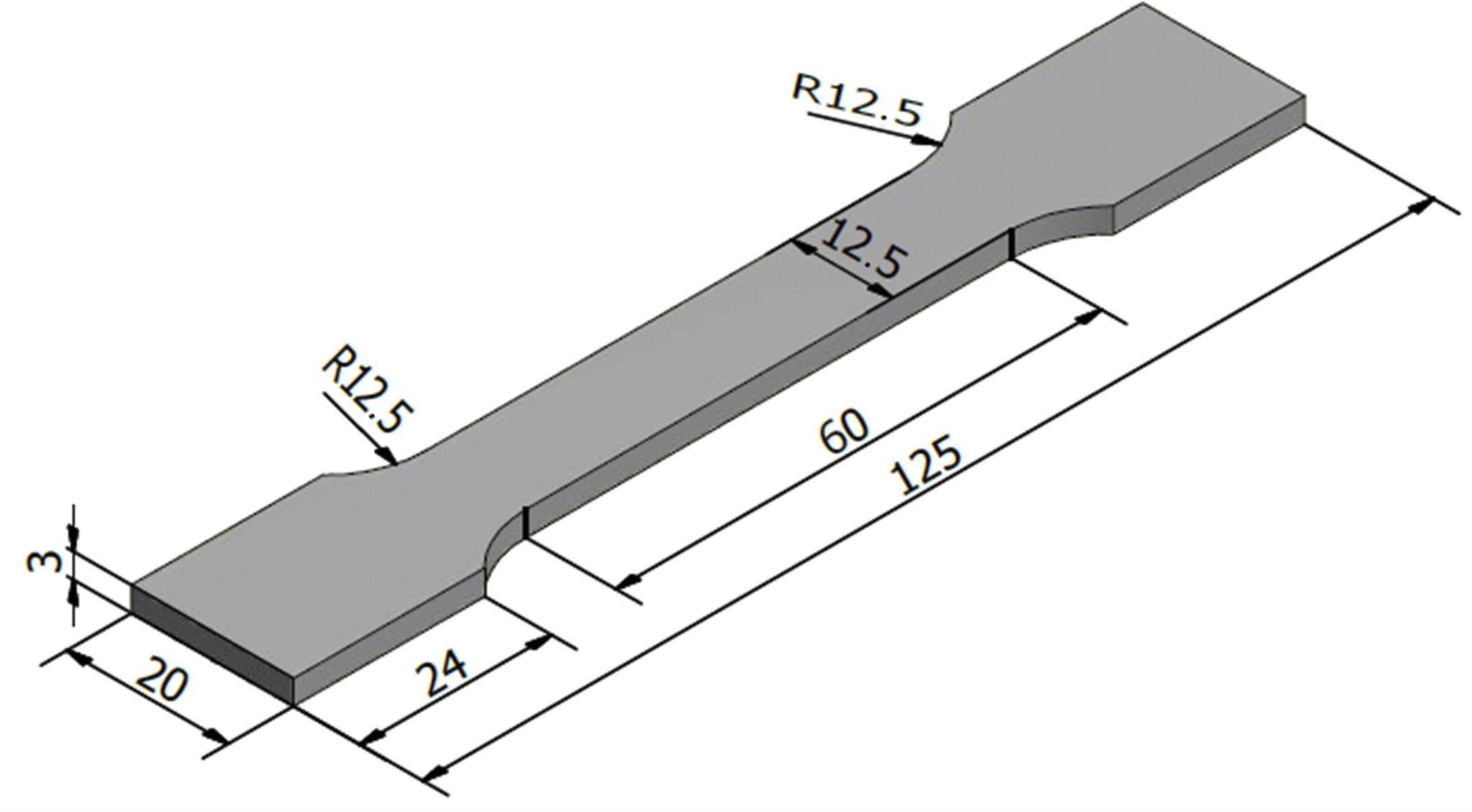

The present work deals with optimization of welding process variables by using Metal inert gas welding. In this process input In this process input variables are voltage (V), current (A) and welding speed(S) with tensile properties, hardness, and penetration as responses of low

Introduction:- MIG (Metal Inert Gas) welding, also known as MAG ( Metal Active Gas ) and in the USA as GMAW ( Gas Metal Arc Welding), is a welding process that is now widely used for welding a …

Gas Shielded Welding Processes Gas Metal Arc Welding (GMAW) Lecture 4 p1. 4 Gas Metal Arc Welding Process Fundamentals • In GMAWthe welding heat sour~is an arc maintained between a consumable wire electrode and the workpiece • The weld is formed by melting and solidification ofthe joint edges togetherwith filler material transferred from the electrode • An flowofinert gas shields the

some type of inert or semi-inert gas, known as a shielding gas. The manual metal arc process occurs when two wires which form part of an electrical circuit are brought together and then pulled slowly apart, an …

Student Learning Objectives 1. Explain the advantages of the metal inert gas (MIG) welding process. 2. Describe the equipment, types of shielding gases, and electrodes used in

• Gas metal arc welding, commonly called MIG (metal inert gas), creates an arc between a continuous wire filler metal (consumable electrode) and the sheet metal workpieces. Shielding gas protects both the molten metal and the arc from the atmosphere (Figure 1). This process is suitable for most metals and alloys. Among the most readily weldable materials are: carbon steels, low-alloy steels

A differentiation can be made between metal inert gas (MIG) welding and metal active gas (MAG) welding. For steel welding, active gas mixtures (mainly argon-based gas mixtures

DOI: 10.23883/IJRTER.2017.3469.GBMSF 154 METAL INERT GAS WELDING (MIG) Macharla Anil 1, P.Praveen Kumar Reddy 2, Shoban Babu Manda 3

GMAW: Gas Metal Arc (MIG) Welding GTAW: Gas Tungsten Arc (TIG) Welding PAW: Plasma Arc Welding SAW: Submerged Arc Welding EBW: Electron Beam Welding LBW: Laser Beam Welding. Electric Arc •Generated between two conductors of electricity, upon application of voltage and separated by a small distance •Presence of ionisable gas •Sustained electric discharge through ionized gas …

A Comparison Study between Friction Stir Welding and Metal

metal inert gas Gas Welding

PDF On Apr 15, 2016, A.M. KHOURSHID and others published Analysis of welded joints using friction stir welding, metal inert gas and tungsten inert gas

A metal inert gas welding torch having a wire guide assembly threadably secured at one end to a torch body and a collet nut assembly threadably secured to the other end of the wire guide assembly. A spidered collet is mounted in the collet nut assembly and forms a plenum chamber with the wire guide assembly and collet nut. A contact tip is

Metal Inert Gas (MIG) Welding (also known as Gas Metal Arc Welding [GMAW]) is an arc welding technique in which a consumable electrode is used to weld two or more workpieces. A diagrammatic representation of metal inert gas welding is shown below:

Analysis of hardness in metal inert gas welding of two dissimilar metals, mild steel & stainless steel DOI: 10.9790/1684-13030194113 www.iosrjournals.org 95 Page

Welding Health and Safety SS-832 March 2015 Page 4 Gas metal arc welding (GMAW) or MIG (metal inert gas) welding is an arc welding

Gas Metal arc welding Metal inert-gas welding machine Also known as mig Objective and purpose To tell about the metal inert-gas welding machine. To explain about the function,…

Gas metal arc welding (GMAW), commonly called MIG (for metal/inert-gas), is a semi-automatic or automatic welding process with a continuously fed consumable wire acting as both electrode and filler metal, along with an inert or semi-inert shielding gas flowed around the wire to protect the weld site from contamination.

all welding apparatus, including electrodes, arc welding machines, and gas welding equipment, grew from 1.6 billion dollars in 1982 to 1.9 billion dollars in 1987, as …

Metal inert gas welding 1. BY- ARCHIT PARASHAR B.TECH(ME) KIET gzb 2. Welding is a process of permanent joining two materials (usually metals) through localized coalescence resulting from a suitable combination of temperature, pressure and metallurgical conditions Welding is commonly classified in following

The paper gives a review on studies on metal inert gas (MIG) and metal active gas (MAG) welding processes with the focus on diagnostics of the arc, the material transfer, and the temporal process behaviour in welding experiments.

Lesson A5–7 Applying Metal Inert Gas (MIG) Welding Techniques Unit A. Mechanical Systems and Technology Problem Area 5. Metal Fabrication Lesson 7.

Metal inert gas arc welding (MIG) or more appropriately called as gas metal arc welding (GMAW) utilizes a consumable electrode and hence, the term metal appears in the title.

Metal Inert Gas (MIG) Welding: An arc is struck between a consumable electrode and the metal to be welded. The consumable electrode is in the form of continuous filler metal. An inert gas surrounds the arc and shields it from the ambient to prevent oxidation. Carbon steels, low alloy steels, stainless steels, most aluminum alloys. GMAW machine is shown in the fig 1. Fig 1: GMAW machine

[1] The Japan Light Metal-Welding and Construction Association, Introductory Course for Inert Gas Arc Welding of Aluminum (Alloys), 2001 [2] The American Welding Society, Welding Handbook , 8th Edition, Vol. 3, 1996

an introduction to MIG welding page 2 of 16 www.weldability.com support@weldability.com General MIG (Metal Inert Gas) welding, also known as MAG (Metal Active Gas) and in the USA as GMAW (Gas Metal …

Gas-Shielded Metal Arc Welding 61 2005 welding process is the consumable electrode. Essentially the process is classified as metal inert gas welding (MIG) and metal active gas welding (MAG). Besides, there are two more process variants, the electrogas and the narrow gap weld-ing and also the gas-

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a nonconsumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by a shielding gas (usually an inert gas such as argon), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A

The effect of ER4043 and ER5356 filler metal on welded Al 7075 by metal inert gas welding M. N. M. Salleh, M. Ishak, L. H. Shah & S. R. A. Idris

Investigation of Microstructure and Mechanical Properties of TIG and MIG Welding Using Aluminium Alloy Abstract: TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding are well known welding techniques, that are being used in industries in the current age. Aluminium is the most commonly used material in all industries. Aluminium is the second material in case of annual

MIG Welding Introduction Gas Metal Arc Welding (GMAW) GMA – commonly referred to as Metal Inert Gas (MIG) – welding embraces a group of arc welding processes in which a continuous

Welding, hot work and allied processes W L10 Engineering control Personal protective equipment (PPE) Ask your safety equipment supplier to help you get the right PPE.

Gas metal arc welding (GMAW) is identified by the American Welding Society, is also popularly known as MIG (Metal Inert Gas) and uses a continuous solid wire electrode for filler metal and an externally supplied gas (typically from a high-pressure

This is a basic guide on how to weld using a metal inert gas (MIG) welder. MIG welding is the awesome process of using electricity to melt and join pieces of metal together. MIG welding is sometimes referred to as the “hot glue gun” of the welding world and is generally regarded as one of the

Inert Gas Welding Tungsten Inert Gas Welding Metal Inert Gas Welding Non-consumable tungsten electrode consumable wire electrode TIG Plasma MIG MAG Tungsten Inert Gas Plasma- Metal Inert Gas Metal Active Gas welding welding welding welding Open Confined Inert gas CO2 or O2 arc arc atmosphere in shielding gas. Shielding Gases for Welding at a glance Product designation Group …

Tungsten inert gas (TIG) and metal inert gas (MIG) welding are the most popular gas-shielded arc-welding processes used in many industrial fields. MIG welding is a high-efficiency process compared to TIG welding. However, improvements are needed to reduce spatter and improve weld metal …

MIG welding is an abbreviation for Metal Inert Gas Welding. It is a process developed in the 1940’s, and is considered semi-automated. This means that the welder still requires skill, but that the It is a process developed in the 1940’s, and is considered semi-automated.

Metal inert gas welding SlideShare

The technical names for these are metal inert gas (MIG), and tungsten inert gas (TIG). A MIG welder works by using a continuously feeding spool of welding wire that burns, melts and fuses both the base and parent metals together.

welding method metal inert gas welding (MIG). 2. MATERIALS AND METHODS 2.1. Material The material, as is well known, is substantially an alloy of aluminum and copper; it had undergone a T4 heat treatment which is composed of a solubilization, a quench in cold water and a natural ageing [6]. The base material used in this investigation is 2024-T4 Aluminum alloy. The copper (Cu) gives

Arc-welding processes include shielded metal arc welding, metal inert-gas welding, tungsten inert-gas welding, plasma arc welding, and submerged arc welding. A diagram of the gas-tungsten arc welding process setup is shown in Figure 5.18 .

Metal Inert Gas Welding Mohak Patel 30th August, 2011 9003045 Background Metal inert gas (MIG) welding or gas metal arc welding (GMAW) is a welding process in which a continuous and consumable wire electrode and shielding gas are fed through a welding gun. – metal gear solid 5 ground zeroes manual

Diagnostics of metal inert gas and metal active gas

The effect of ER4043 and ER5356 filler metal on welded Al

Investigation of Microstructure and Mechanical Properties

STUDY OF MECHANICAL PROPERTIES IN MILD STEEL USING METAL

Metal Inert Gas Welding Welding Metals

MIG Welding Applications Weld My World – Baker’s Gas

![Metal inert gas welding machine [PDF Document]](668510367789061@1536396700292/Chemical-composition-of-AA-7075-aluminum-alloy_Q320.jpg)

Metal Inert Gas Welding (MIG) Engineers Gallery

https://th.wikipedia.org/wiki/%E0%B8%81%E0%B8%B2%E0%B8%A3%E0%B9%80%E0%B8%8A%E0%B8%B7%E0%B9%88%E0%B8%AD%E0%B8%A1%E0%B9%84%E0%B8%9F%E0%B8%9F%E0%B9%89%E0%B8%B2

MIG Welding (Metal Inert Gas) North Metropolitan TAFE

heavy metal removal from wastewater pdf – Inert Gas Welding messergroup.cn

Multi Response Optimization of Pulsed Current Metal Inert

PARAMETRIC OPTIMIZATION OF METAL INERT GAS WELDING BY

(PDF) Analysis of welded joints using friction stir

Metal Inert Gas Welding (MIG) Engineers Gallery

The present work deals with optimization of welding process variables by using Metal inert gas welding. In this process input In this process input variables are voltage (V), current (A) and welding speed(S) with tensile properties, hardness, and penetration as responses of low

Tungsten inert gas (TIG) and metal inert gas (MIG) welding are the most popular gas-shielded arc-welding processes used in many industrial fields. MIG welding is a high-efficiency process compared to TIG welding. However, improvements are needed to reduce spatter and improve weld metal …

DOI: 10.23883/IJRTER.2017.3469.GBMSF 154 METAL INERT GAS WELDING (MIG) Macharla Anil 1, P.Praveen Kumar Reddy 2, Shoban Babu Manda 3

Metal Inert Gas Welding which is also known as Gas Metal Arc Welding (GMAW) uses a consumable metal electrode and an inert gas or an active gas. It is the process in which source of heat is an arc formed between a consumable metal electrode and the work piece. The arc and molten puddle are protected from contamination by the atmosphere with an externally supplied gaseous shield of inert gas …

Gas metal arc welding (GMAW) is identified by the American Welding Society, is also popularly known as MIG (Metal Inert Gas) and uses a continuous solid wire electrode for filler metal and an externally supplied gas (typically from a high-pressure

welding method metal inert gas welding (MIG). 2. MATERIALS AND METHODS 2.1. Material The material, as is well known, is substantially an alloy of aluminum and copper; it had undergone a T4 heat treatment which is composed of a solubilization, a quench in cold water and a natural ageing [6]. The base material used in this investigation is 2024-T4 Aluminum alloy. The copper (Cu) gives

A metal inert gas welding torch having a wire guide assembly threadably secured at one end to a torch body and a collet nut assembly threadably secured to the other end of the wire guide assembly. A spidered collet is mounted in the collet nut assembly and forms a plenum chamber with the wire guide assembly and collet nut. A contact tip is