Fabrication of titania nanofibers by electrospinning pdf

Fabrication of titania nanofibers by electrospinning pdf

The applications of the nanofibers containing chitosan such as enzyme immobilization, filtration, wound dressing, tissue engineering, drug delivery and catalysis are also summarized in detail. Keywords: nanomaterials, chitosan, nanofibers, electrospinning, applications

Fabrication of Melt Spun Polypropylene Nanofibers by Forcespinning Bharath Raghavan, Ph.D1, Haidy Soto2, the traditional electrospinning (research tool) method to enhance nanofiber production. Theron et. al studied a multiple needle system (7-9 needles) using equidistantly arranged needles, they observed that behavior of border jets along the linear array were different from that of

Ceramic-derived materials have shown enhanced osteogenic potential for bone tissue engineering applications. Silica is the major component of bioglass, and titania, the oxide complex of titanium, has been found to enhance osteoblast differentiation.

JapaneseJournal ol Applied Physics 50 (2011) 01BJ16 REGULARPAPER DOI: 10 1143/JJAP.5001BJ16 Fabrication and Utilization of Titania Nanofibers from Natural Leucoxene Mineral

The titania–polymer hybrid nanofibers so formed than were calcined to remove the polymer and, hence, forming hollow titania nanofibers. A similar approach done on polymer nanospheres obtained after the heat treatment of polymer nanofibers, led to the formation of hollow titania nanospheres.

The electrospinning process uses high voltage to create an electric field between a droplet of polymer solution at the tip of a needle and a collector plate (see Figure 1&2).

In this work, TiO 2 nanofibers with various morphology including multi-channel, hollow, irregular hollow and mesoporous were fabricated by regulating the ratio of TBT to paraffin oil via microemulsion electrospinning followed by calcination, the schematic illustration was demonstrated in Fig. 1.

Home / Resources / Journals / AMMTIAC Quarterly, Vol. 3, No. 3 – Antimicrobial Titania Nanofibers AMMTIAC Quarterly, Vol. 3, No. 3 – Antimicrobial Titania Nanofibers PDF

applications in the fabrication of dye sensitized solar cells, photocatalysts, gas sensors, and water treatment systems, among others, have been produced at large yield rates utilizing the Forcespinning® (FS) technology. This study presents the results of research performed to determine optimal processing parameters to create TiO 2 nanofibers at a high production rate. The effects of polymer

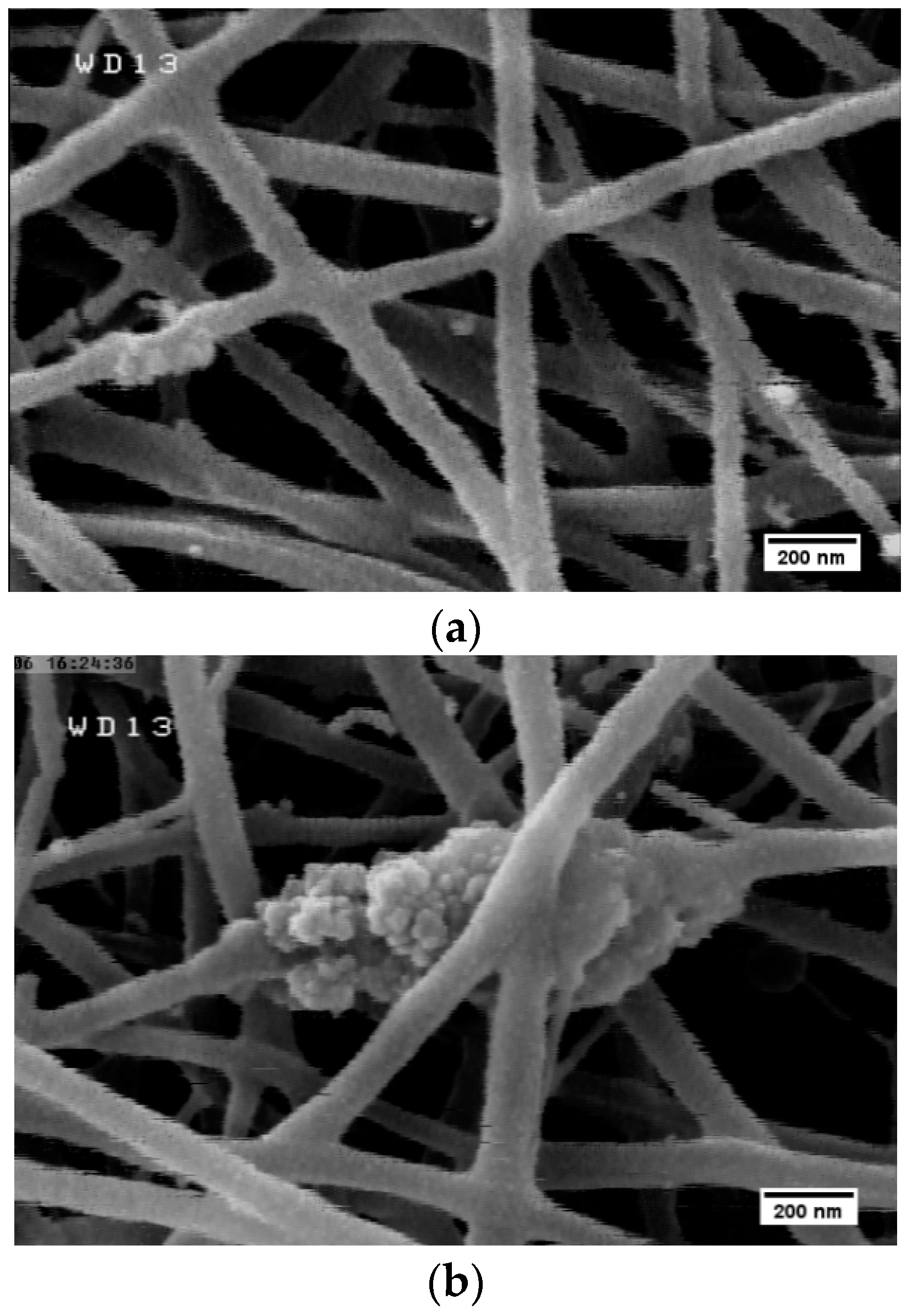

Well-aligned TiO2 nanofibers were grown using the near-field electrospinning technique onto a silicon dioxide substrate. These nanofibers were several millimeters long with a diameter of about 200–400nm. The scanning electron microscopy showed the presence of microcystallites, whose crystalline structure was evaluated by x-ray diffraction

Fabrication of hierarchically porous TiO 2 nanofibers by microemulsion electrospinning and their application as anode material for lithium-ion batteries

FABRICATION OF CHITOSAN NANOFIBERS MEMBRANE AND ITS TREATMENT Fekri A. Ahmed Ali, Sajjad Haider, Waheed A. Al-Masry, Yousef Al-Zeghaye Department of Chemical Engineering, College of Engineering, King Saud University

Small 2011 Jul 17;7(13):1779-83. Epub 2011 May 17. Beijing National Laboratory for Molecular Sciences, Key Laboratory of Organic Solids, Institute of Chemistry, Chinese Academy of Sciences, Beijing 100190, P. R. China.

Fabrication of doped Titania (TiO2) nanofibers to serve as catalysts in NH3-Selective CatalyticReduction (SCR) By Debora Marani, Rafael Hubert Silva, Apiwat Dankeaw, Mads Gudik-Sørensen, Kion Norrman, Kent Kammer Hansen and Vincenzo Esposito

Electrospinning of ceramic nanofibers: Fabrication, assembly and applications Hui WU,Wei PAN * ,Dandan LIN,Heping LI State Key Lab of New Ceramic and Fine Processing, Department of Materials Science and Engineering, Tsinghua University, Beijing 100084, China

Fabrication and characterization of electrospun titania nanofibers Ramya Chandrasekar Æ Lifeng Zhang Æ Jane Y. Howe Æ Nyle E. Hedin Æ Yan Zhang Æ Hao Fong

Fabrication of Titania Nanofibers by Electrospinning

Fabrication and characterization of electrospun titania

Flexible mats of titania fibers are prepared by calcination of electrospun polyvinylpyrrolidone fibers containing titanium isopropoxide precursor. Structural investigation of the calcinated nanofibers by X-ray diffraction (XRD) and electron diffraction (ED) combined with the morphologies by scanning

By combining electrospinning and sol-gel chemistry, materials are processed as nanofibers with the catalytic components ( e. g. V 2 O 5 -WO 3 ) incorporated as dopants into the supporting anatase phase ( …

Fabrication of titanium oxide nanofibers containing silver nanoparticles Faheem A. Sheikha,*, Muzafar A. Kanjwalb, Fabrication of nanofibers by electrospinning To produce nanofibers by electrospinning from sol-gels the following procedure was adopted. Typically, a sol-gel was prepared by mixing Ti(Iso) and PVAc (20 wt%, in DMF) with a weight ratio of 2 : 3. To fabricate the sol-gel

Electrospinning is a popular technique to produce structures in the form of nanofibers. These These nanofibers can be used for many applications such as filtration …

A facile method for the fabrication of TiO 2 nanofiber–nanoparticle nanohybrids for dye-sensitized solar cell applications via co-electrospraying–electrospinning route. Optimized nanohybrid composition with higher particle loading showed a power conversion efficiency of 9.15%.

Abstract This paper describes a simple and convenient procedure for fabricating polycrystalline titania nanofibers with controllable diameter and porous structures.

Fabrication of Poly(Caprolactone) Nanofibers by Electrospinning Athira K. S.*, Pallab Sanpui, Kaushik Chatterjee Biomaterials and Tissue Engineering Laboratory, Department of Materials Engineering, Indian Institute of Science, Bangalore, India *Corresponding author: athiraiisc@gmail.com Received October 28, 2014; Revised November 06, 2014; Accepted November 09, 2014 Abstract Nanofibers …

Nanofibers can be produced by several processes, including melt blowing, interfacial polymerization, electrospinning, and antisolvent-induced polymer precipitation . Recently, electrospinning is the main choice among researchers due to the great benefit of producing ultrafine nanofiber structures.

Titania nanofibers were fabricated by drying electrospun Ti02/polyvinylpyrrolidone nanofibers for 5 h in air and subsequent annealing for 3 h at temperatures from 450 °C to 550 °C in air. To

Fabrication of carbon nanofibers with Si nanoparticle-stuffed cylindrical multi-channels via coaxial electrospinning and their anodic performance

Titania (TiO2) nanofibers were fabricated by electrospinning three representative spin dopes made of titanium (IV) n-butoxide (TNBT) and polyvinylpyrrolidone (PVP) with the TNBT/PVP mass ratio being…

Zanjani, Jamal Seyyed Monfared Saner Okan, Burcu Menceloglu, Yusuf Ziya and Yildiz, Mehmet 2015. Design and fabrication of multi-walled hollow nanofibers by triaxial electrospinning as reinforcing agents in nanocomposites.

Rapid fabrication of titania nanofibers by electrospinning Rapid fabrication of titania nanofibers by electrospinning Li, Dan 2003-11-25 00:00:00 This paper describes a simple and convenient procedure for fabricating polycrystalline titania nanofibers with controllable diameter and porous structures.

Titanium dioxide nanofibers with diameter ranging to several nanometers were synthesized via electrospinning technique. The precursor solution was prepared by mixing the polyvinylpyrrolidone, PVP (MW~1,300,000) in ethanol, meanwhile titanium tetraisopropoxide, TTIP in acetic acid was slowly added into the solution under a vigorous stirring. The

Nitanan et al Trop J Pharm Res, February 2014; 13(2): 192 Many polymers are used to produce nanofibers by electrospinning. Polystyrene (PS) is one of

Abstract: Novel functional poly (ethylene terephthalate) (PET)/TiO2 nanofibers have been prepared by electrospinning the homogeneous solution of PET and titania precursor, tetra-n-butyl titanate (TBT), in trifluoroacitic acid (TFA).

Fabrication of PVA/GO nanofibers by electrospinning process for the removal of lead (II) and copper (II) ions from aqueous solutions Farnoosh Rezaeifard

Fabrication of electrospun silica-titania nanofibers with different silica content and evaluation of the morphology and osteoinductive properties. Journal of Biomedical Materials Research – …

The influence of metal nanoparticle on the fabrication of carbon fiber and its properties was also investigated by the addition of a metal salt, nickel(II) acetate tetrahydrate [(CH3COO)2 Ni·4H2O], to the PVA spinning solution. Noticeably, after incorporation of nickel (Ni) nanoparticle continuous electrospinning was realized at lower polymer concentration than that of neat PVA. Moreover

Read “Fabrication and characterization of electrospun titania nanofibers, Journal of Materials Science” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Abstract. Porous carbon nanofibers were prepared through electrospinning a blend solution of polyacrylonitrile and poly(L-lactide), followed by carbonization at different …

Electrospun Titania Oxide Nanofibers Coupled Zinc Oxide Nanobranches as a Novel Nanostructure for Lithium Ion Batteries Applications Muzafar A. Kanjwal,1 Nasser A. M. Barakat,2 Faheem A. Sheikh,2 and Hak Yong Kim2 1 Department of Polymer Nano Science and Technology, Chonbuk National University, Jeonju 561-756, 2 Organic Materials and Fibers Engineering, Chonbuk National …

Electrospun Titania Nanofibers from a Benign and

Abstract To endow nanofibers with the desirable antibacterial and mechanical properties, a facile strategy using Pickering emulsion (PE) electrospinning is proposed to prepare functional nanofibers with core/shell structure for the first time.

TiO 2-based nanofibers were synthesized using a sol–gel method and electrospinning technique. The as-spun composite fibers were heat-treated at different temperatures (500°C, 550°C, 600°C, and 650°C) and atmospheres (ammonia and nitrogen) for 4 h.

This paper describes a simple and convenient procedure for fabricating polycrystalline titania nanofibers with controllable diameter and porous structures.

Titania nano crystals were prepared at ambient temperature in a liquid media using titanium tetrabutoxide as precursor, and the crystallization of amorphous precursor was preceded by peptizing with acid and then refluxing for a periodic time in homothermal water-bath.

文章 . A. M. Azad, S. McKelvey, and Z. Al-Firdaus, “Fabrication of antimicrobial titania nanofibers by electrospinning,” Advanced Materials, Manufacturing, and

A Modified Bubble Electrospinning for Fabrication of Nanofibers, Journal of Nano Research, Vol. 23, 2013, pp. 125-128 [10] Chen, R.-X., On Surface Tension of a …

Here we demonstrate that titania nanofibers can of templates with titania (or a precursor to this material), be conveniently prepared by electrospinning an … – the document of metal gear solid 2 Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other

Electrospinning: a simple and versatile technique for producing ceramic nanofibers and nanotubes D Li, JT McCann, Y Xia, M Marquez Journal of the American Ceramic Society 89 (6), 1861-1869 , 2006

For the fabrication of titania nanofibers incorporated with SnO 2 nanoparticles, tin tetraisopropoxide (1 g) was dissolved in mineral oil (5 mL). The as-spun fibers were then calcined in …

present the fabrication and characterization of TiO 2 measurement. FTIR analysis showed the peaks from 800-500 cm-1 corresponding to the stretching of Ti-O. Keywords: TiO2, nanofibers, sol-gel, electrospinning, anatase and rutile phase. 1. INTRODUCTION Titanium dioxide (TiO 2) and its composite Nanofibers has innumerous application in various fields such as sensors, solar cells, …

Electrospun Nanofibers offers systematic and comprehensive coverage for academic researchers, industry professionals, and postgraduate students working in the field of fiber science. Electrospinning is the most commercially successful process for the production of nanofibers and rising demand is driving research and development in this field.

Fabrication of electrospun silica-titania nanofibers with different silica content and evaluation of the morphology and osteoinductive properties Xiaokun Wang et al 2012 Journal of Biomedical Materials Research Part A n/a

2.1. Preparation of Polymeric and Titanium Precursors . The pure and doped titania fibers in nonwoven format were fabricated by electrospinning using an indigenously assembled setup, described in details elsewhere [15, 16].

nanofibers are useful and valid to enhance cellular adherence and proliferation because of their advantages of large aspect ratio, structural uniformity, and better mechanical properties.

Gold-doped titanium dioxide (TiO2:Au) nanofibers were prepared by a combination of an electrospinning method and sputtering technology and characterized by scanning electron microscopy and X-ray photoelectron spectroscopy. The results show that the morphologies of Au-deposited TiO2 nanofibers can be well controlled by the sputtering time. The

Bactericidal efficacy of electrospun pure and Fe-doped titania nanofibers Abdul-Majeed Azada) and Ryan Hershey Department of Chemical Engineering, The University of Toledo, Toledo, Ohio 435606-3390

This paper describes a procedure based on electrospinning for generating nanofibers of anatase with controllable diameters and porous structures.

Morphology and crystalline phase study of electrospun TiO2

Ultrathin fibers of PVP/ZnTiO3 composite were prepared through sol-gel processing and electrospinning technique. After calcined of the above precursor fibers at 600°C, the spinel ZnTiO3 nanofibers, with a diameter of 50-150nm, were successfully obtained. The fibers were characterized by X-ray diffraction (XRD), scanning electron microscopy

Indian Journal of Chemistry Vol. 48A, January 2009, pp. 69-72 Fabrication of Gd 2O3:Eu 3+ nanofibers by electrospinning X Y Zhang, C Z Zhao, L Y Chai & W Liu*

The diameters of CeO 2 hollow nanofibers (300 nm at 600 °C and 600 nm at 800 °C) were smaller than those of PVP/Ce(NO 3) 3 composite fibers (1–2 μm). CeO 2 hollow nanofibers were obtained at 600 °C and CeO 2 hollow and porous nanofibers formed by nanoparticles were obtained at 800 °C.

Fabrication of titania nanostructures using core–shell

Physical Characterization of Titanium Dioxide Nanofiber

Single and Bicomponent Electrospun Nanofibrous Mats. (Under the direction of Dr. Russell E. Gorga). Nanofibers were produced using relatively new electrospinning technique. Single layer nanofibers were fabricated using nylon-6. Several parameters such as polymer molecular weight, concentration, surface tension, applied electric voltage, distance between tip to grounded electrode and feed rate

In this article, we describe a microfluidic approach to fabricate hollow and core/sheath nanofibers by electrospinning. Key benefits in using microfluidic devices for nanofiber synthesis include rapid prototyping, ease of fabrication, and the ability

29/11/2011 · See D. Li et al., “Fabrication of titania nanofibers by electrospinning,” Nano Letters, vol. 3, pp. 555-560 (2003); and D. Li et al., “Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays,” Nano Letters, vol. 3, pp. 1167-1171 (2003). Because the composite gel fibers produced by these processes have contained high levels of organic polymers (typically, about

attributes, this paper describes the fabrication and characterization of non-woven titania nanofibers, using a simpler and more benign precursor than that has been usually used the case of titania …

The antibacterial activity and the acting mechanism of Zn-doped titania nanofibers against bacteria were investigated by calculation of minimum inhibitory concentration and analyzing the morphology of the bacterial cells following the treatment with nanofibers solution.

Direct fabrication of cerium oxide hollow nanofibers by

Younan Xia Google Scholar Citations

Fabrication and Characterization of Heterostructural CoFe 2O 4/ Pb(Zr 0.52Ti 0.48)O 3 Nanofibers by Electrospinning JIN-CAI ZHENG,XIANG-QIAN SHEN,* CHUN-YING MIN,

The influence of the blend ratio of PVA to PTFE and electrospinning technical parameters on the morphology and diameter of the composite nanofibers were investigated. According to the result of thermogravimetric analyzer analysis, the composite membrane was sintered at 390 °C. The membranes were then characterized by differential scanning calorimetry, attenuated total reflection-Fourier

Electrospun Titanium Dioxide Nanofibers: Fabrication, Properties and Its Application in Photo-Oxidative Degradation of Methyl Orange (MO) 6 Pages. Electrospun Titanium Dioxide Nanofibers: Fabrication, Properties and Its Application in Photo-Oxidative Degradation of Methyl Orange (MO) Uploaded by. Vahid Jabbari. Download with Google Download with Facebook or download with email. …

Fabrication and Characterization O Pb(Zr Ti Nanofibers by

Physical Characteristics of Titania Nanofibers Synthesized by Sol-Gel and Electrospinning Techniques Soo-Jin Park, Yong C. Kang, Ju Y. Park, Ed A. …

2. Experimental Details. The TiO 2 nanofibers were fabricated as follows. Based on a sol-gel processing, 1.0 mmol of titanium tetraisopropoxide (TIP, Ti(OCH(CH 3) 2) 4, Aldrich) was dissolved in 4 mL of glacial acetic acid and 10 mL of methanol with stirring at …

Authors: Shanhu Liu Photocatalyst Group, Kanagawa Academy of Science and Technology, Kawasaki, Kanagawa, Japan and Institute of Environmental and Analytical Sciences, College of Chemistry and Chemical Engineering, He Baoshun Liu Photocatalyst Group, Kanagawa Academy of …

Fabrication of Titania Nanofibers by Electrospinning Dan Li , and Younan Xia * Department of Chemistry, University of Washington, Seattle, Washington 98195-1700

Since a published patent [1], considered the historical origin of the electrospinning (ES) technology, described a polymer material, cellulose acetate (CA), the nanofiber fabrication technique and cellulose-related materials have jointly studied for a long time.

Fabrication of hierarchically porous TiO2 nanofibers by

Electrospun Titania Oxide Nanofibers Coupled Zinc

– Fabrication of Novel Poly (Ethylene Terephthalate)/TiO2

Investigation of the Physical Characteristics of Titania

AMMTIAC Quarterly Vol. 3 No. 3 Antimicrobial Titania

YouTube Embed: No video/playlist ID has been supplied

Fabrication and Characterization of New Composite Tio2

Antibacterial activity and interaction mechanism of

Fabrication of titania nanostructures using core–shell

Fabrication and Characterization of Heterostructural CoFe 2O 4/ Pb(Zr 0.52Ti 0.48)O 3 Nanofibers by Electrospinning JIN-CAI ZHENG,XIANG-QIAN SHEN,* CHUN-YING MIN,

JapaneseJournal ol Applied Physics 50 (2011) 01BJ16 REGULARPAPER DOI: 10 1143/JJAP.5001BJ16 Fabrication and Utilization of Titania Nanofibers from Natural Leucoxene Mineral

Titania nanofibers were fabricated by drying electrospun Ti02/polyvinylpyrrolidone nanofibers for 5 h in air and subsequent annealing for 3 h at temperatures from 450 °C to 550 °C in air. To

Indian Journal of Chemistry Vol. 48A, January 2009, pp. 69-72 Fabrication of Gd 2O3:Eu 3 nanofibers by electrospinning X Y Zhang, C Z Zhao, L Y Chai & W Liu*

Titania (TiO2) nanofibers were fabricated by electrospinning three representative spin dopes made of titanium (IV) n-butoxide (TNBT) and polyvinylpyrrolidone (PVP) with the TNBT/PVP mass ratio being…

applications in the fabrication of dye sensitized solar cells, photocatalysts, gas sensors, and water treatment systems, among others, have been produced at large yield rates utilizing the Forcespinning® (FS) technology. This study presents the results of research performed to determine optimal processing parameters to create TiO 2 nanofibers at a high production rate. The effects of polymer

文章 . A. M. Azad, S. McKelvey, and Z. Al-Firdaus, “Fabrication of antimicrobial titania nanofibers by electrospinning,” Advanced Materials, Manufacturing, and

Here we demonstrate that titania nanofibers can of templates with titania (or a precursor to this material), be conveniently prepared by electrospinning an …

Fabrication of PVA/GO nanofibers by electrospinning process for the removal of lead (II) and copper (II) ions from aqueous solutions Farnoosh Rezaeifard

Nanofibers can be produced by several processes, including melt blowing, interfacial polymerization, electrospinning, and antisolvent-induced polymer precipitation . Recently, electrospinning is the main choice among researchers due to the great benefit of producing ultrafine nanofiber structures.

The titania–polymer hybrid nanofibers so formed than were calcined to remove the polymer and, hence, forming hollow titania nanofibers. A similar approach done on polymer nanospheres obtained after the heat treatment of polymer nanofibers, led to the formation of hollow titania nanospheres.

Abstract: Novel functional poly (ethylene terephthalate) (PET)/TiO2 nanofibers have been prepared by electrospinning the homogeneous solution of PET and titania precursor, tetra-n-butyl titanate (TBT), in trifluoroacitic acid (TFA).

present the fabrication and characterization of TiO 2 measurement. FTIR analysis showed the peaks from 800-500 cm-1 corresponding to the stretching of Ti-O. Keywords: TiO2, nanofibers, sol-gel, electrospinning, anatase and rutile phase. 1. INTRODUCTION Titanium dioxide (TiO 2) and its composite Nanofibers has innumerous application in various fields such as sensors, solar cells, …

Electrospinning of ceramic nanofibers: Fabrication, assembly and applications Hui WU,Wei PAN * ,Dandan LIN,Heping LI State Key Lab of New Ceramic and Fine Processing, Department of Materials Science and Engineering, Tsinghua University, Beijing 100084, China

Flexible mats of titania fibers are prepared by calcination of electrospun polyvinylpyrrolidone fibers containing titanium isopropoxide precursor. Structural investigation of the calcinated nanofibers by X-ray diffraction (XRD) and electron diffraction (ED) combined with the morphologies by scanning

Fabrication of electrospun silica-titania nanofibers with different silica content and evaluation of the morphology and osteoinductive properties Xiaokun Wang et al 2012 Journal of Biomedical Materials Research Part A n/a

Bactericidal efficacy of electrospun pure and Fe-doped

The effects of atmosphere and calcined temperature on

Antibacterial activity and interaction mechanism of