Aws filler metal specification pdf

Aws filler metal specification pdf

A1.4 In some cases, the composition of bare filler metal classified in this specification may differ from that of core wire used for the corresponding classification of covered electrodes classified in AWS A5.4, Specification for Stainless Steel Electrodes for Shielded Metal Arc Welding. Caution, therefore, should be exercised regarding the use of core wire from a covered electrode as bare

Filler Metal Procurement Guidelines. testing requirements and procedures. in this case. and packaging for filler metals are specified in the filler metal specification and are not intended to be duplicated or modified in this specification. method of manufacture. General Information The general requirements. The complete list of filler metal specifications is given for reference in the back of

Washington Alloy Phos-Bronze A filler metal is used for MIG and TIG welding of tin-bronze base metals such as 509 to 519 series, for brass and for overlay welding of steel. Phos-Bronze A contains approximately 5% tin and up to 0.35% phosphorus.

Relevance of filler metal variables depend on process AWS Classification . 6 . SFA-5.28 . All Classifications . 6 . SFA-5.18 . All Classifications . Module 7 – Summary 7-18 Weld Procedure Qualification . Procedure Qualification – Filler Metal Variables QW-404.5 – The welding wire was ER80S-D2 for GTAW and ER70S-6 for GMAW SAME ASME Section II specifications apply to …

The deposition rate of solid wires is very high when compared to that of coated elec-trodes, but is somewhat lower than the deposition rate of flux cored electrodes. 6.4 AWS SPECIFICATION A5.18-93 6.4.0.1 This AWS specification is entitled Specification for Carbon Steel Filler Metals for Gas Shielded Arc Welding.

Metal thickness of ¾” or greater for fillet welds sometimes employs a double vee bevel of 50 deg or greater included vee with 3/32 to 1/8 inch land thickness on the abutting member. 2.

APPENDIX B Filler Metal Comparison Chart ABS-AWS The AWS Filler metals listed on the following pages are those which it is felt, based on a review of past experience, are acceptable and meet the minimum Bureau requirements for the indicated grade.

AWS Filler Metal Specification AWS Classification F-Number Consumable Insert Weld deposit thickness Position Groove – Sheet & Tube ≥ 1” Groove – Tube < 1” Fillet – Sheet & Tube Clad / Hardfacing Vertical Progression Backing Gas OFW Fuel Gas GMAW Transfer Mode

INCONEL® Filler Metal 625. INCONEL® Filler Metal 625 is used for gas-metal-arc and gas-tungsten-arc welding of INCONEL® alloy 625, INCOLOY® alloy 825, INCOLOY® alloy 25-6MO, and a range of high alloy austenitic and super austenitic stainless steels.

Selecting Filler Metals: Electrodes for Stress Relieved Applications Introduction This is the third and final installment in a series on selecting filler metals. Many filler metals are classified in the “as-welded” condition. This simply means that no subsequent heat treat-ing operation was performed following welding and prior to mechanical test-ing. Other electrodes are classified in the

RECOMMENDED SHIELDING GASESfor Welding Material Sales Alloy Filler Metals * Welding Material Sales is continuously updating and adding packaging options to meet todays changing market. Please call for an up-to-date list of available packaging.

Abstract. This specification prescribes the requirements for the classification of filler metals for brazing and braze welding. The chemical composition, physical form, and packaging of more than 75 brazing filler metals are specified.

Lesson 6 Carbon & Low Alloy Steel Filler Metals for the

AWS 5.14 ERNiCrMo-3 The Welding Warehouse Inc.

AWS A5.10 Bare Aluminum & Aluminum-Alloy Welding Electrodes & Rods. ER1100 Alloy 1100 Alloy 1100 is highly resistant to chemical attack and weathering. It is a relatively soft alloy that is very formable and is used extensively in thin gauge and foil products. It has good welding characteristics and it is also used as a filler alloy for welding purposes. A desirable characteristic of the alloy

AWS A5.02/A5.02M:2007Specification for Filler Metal Standard Sizes, Packaging, and Physical Attributes, Includes Errata (2008) Edition: 1st American Welding Society / 06-Nov-2006 / 30 pages ISBN: 0871710595 Scope 1.1 This specification prescribes requirements for standard sizes and packages of welding filler metals and their physical attributes

the filler metals used do not have an AWS Classification available at this time. When you are faced with a particular material or combination of materials not shown in these tables, please consult the manufacturer or the DFD

AWS A5.XX – XX: All Applicable Filler Metal Specifications AWS D1.1/D1.1M Structural Welding Code – Steel AWS D1.5/1.5M Bridge Welding Code International Organization for Standardization/ International Electrotechnical Commission ISO/IEC 17025:1999 General Requirements for the Competence of the Testing and Calibration Laboratories Definitions Bearing Contact Area: the overlapping area

Aws filler metal specification keyword after analyzing the system lists the list of keywords related and the list of websites with related content, in addition you can see which keywords most interested customers on the this website

Prescribes size, package, appearance, and identification requirments for filler metals for solid, tubular, bare, covered, and stripped electrodes used in fusion process, but not br… Read More A5.3/A5.3M:1999(R2007) SPECIFICATION FOR ALUMINUM AND ALUMINUM ALLOY ELECTRODES FOR SHIELDED METAL ARC WELDING (HISTORICAL)

AWS A5.8M/A5.8:2011-AMD1, Specification for Filler Metals for Brazing and Braze Welding (errata issued for Table 4) AWS A5.9/A5.9M:2017, Welding Consumables – Wire Electrodes, Strip Electrodes, Wires, and Rods for Arc Welding of Stainless and Heat Resisting Steels – Classification

4 Gas Metal Arc Welding or ANSI/AWS A5.28, Specifica-tion for Low Alloy Steel Filler Metals for Gas Shielded Arc Welding, ANSI/AWS A5.20, Specification for Car-

Filler Metal Allowed in Prequalified WPS: Only Filler Metal-Base Metal Group Combinations for Matching Strength as shown in Table 3.1 of AWS D1.1 (Size and other limit on electrode for prequalification of each

Comparison of Welding Consumables Commercially available welding consumables that conform with A5 filler metal classifications. The AWS Filler Metal Comparison Charts (AWS …

The American Welding Society (AWS) publishes specifications for a wide variety of welding filler metals. These specifications are a series of rules and standards used by the welding industry to classify welding electrodes.

AWS Filler Metal Specifications and Related Documents Abstract – (Show below) – (Hide below) Specifies the requirements for the classification of carbon steel electrodes for shielded metal …

Base metal; Filler metal; Process( es); Techniques ; and Welding conditions ADVANTAGES Eliminate the possibility of reject of weld Eliminate project delay Cost effectiveness Enhance quality (both in weld and project) Able to identify problems when, or even before the problems occur PROCEDURE QULAIFICATION Approaches to procedure approval by Pre -qualified procedures Actual procedure

Filler metal for exposed, bare, unpainted applications of CSA G40.21 350A, 350AT, 400A, 400AT and ASTM A242 and A588 shall meet requirements of clause 5.2.1.5, 5.2.1.6 and table 5.1 of …

Filler Metal Product Form requirements of Section IX of the ASME Boiler and Pressure Vessel Code. 03/08 . DT2320 Welding Checklist – Wisconsin Department of Transportation

05 05 22 Metal Welding

FLUX-COREDGAS-SHIELDED WIRES LOW ALLOY TM-811A1 Features: • •Deposits weld metal with 1/2% molybdenum to prevent tensile stress deterioration

The requirements in This specification prescribes the requirements for classification of solid and composite stainless steel electrodes (both as wire and strip) for gas metal arc wel . and completely the required filler metal specification.

built a reputation for delivering high quality filler metal products for the industrial user. Known for their quality, consistency and performance, AWS A5.1: E6013 DESCRIPTION: Austarc 13S is a popular blue and white striped mild steel general purpose electrode for welding in down hand and vertical up positions. It has a soft and stable arc and produces flat, uniform fillet welds with ease

filler metal in AWS specifications and for consumable inserts in the Military Specification. 5 See A3 (in Annex A) for further information concerning acceptance and testing of material shipped, and AWS A5.01. 5. Certification By affixing the AWS specification and classification designations to the packaging, or the classification to the product, the manufacturer certifi es that the product

In filler metal specification AWS A5.1, low hydrogen carbon steel SMAW electrodes are identified with the last “X” number in the designator EXXXX as a 5, 6 or 8.

Prepared by the American Welding Society (AWS) A5 Committee on Filler Metals and Allied Materials Under the Direction of the AWS Technical Activities Committee Approved by the AWS Board of Directors Abstract This specification prescribes the requirements for classification of low-alloy steel covered electrodes used for shielded metal arc welding. – sheet metal tools and their uses pdf The Forms in through A5 are suggested forms intended to serve as a check list for detailing filler metal requirements for procurement. and. Inc. and packaging for filler metals are specified in the filler metal specification and are not intended to be duplicated or modified in this specification. as the filler metal specification requires).) Al. and the supplemental designator is H4R. is the

filler metal: Specification ASTM B 32 containing less than 0.2% lead (Pb) AWS Classification 300 Form 0.125″ wire Method of Application Manual face feed

SPECIFICATION 1000-Rebar/4140 0 9/15/2006 9/15/2006 1000-R/4140 N/A N/A A-706 Grade 60 Rebar A-193 Grade B7/AISI 4140 0.250 1.125 0.221 1.250 Flare Bevel Partial Penetration Metal Remove loose rust and scale N/A N/A 5.5 5.5 44 E8018 E9018 3/32 1/8 1/8 500 500 Vertical Up 700 * * * N/A N/A N/A X WPS – DATE: WELDING PROCESS: and SUPPORTING PQR: **APPLICABILITY** ASME: AWS: …

buy aws a5.8/a5.8m : 2011 specification for filler metals for brazing and braze welding from sai global

specification for filler metals for brazing and braze welding a5.11/a5.11m specification for nickel and nickel alloy welding electrodes for shielded metal arc welding a5.14/a5.14m specification for nickel and nickel alloy bare welding electrodes and rods a5.18/a5.18m specification for carbon steel electrodes and rods for gas sheilded arc welding a5.20 carbon steel electrodes for flux cored arc

INCONEL Filler Metal 718 is used for gas-tungsten-arc welding of INCONEL alloys 718, 706 and X-750. The weld metal is age hardenable and has mechanical properties

Skip to main content Skip to primary navigation Menu Home Home About this portal Latest updates Print Save Email Resource detail Citations AWS A5.18 Specification For Carbon Steel Filler Metals For

Matching filler metal requirements shall conform with AWS D1.1 and AWS D1.5, as applicable. B. Electrodes for sheet steel shall conform with AWS A5 Series Standards and shall be coated rods

AWS A5.10 Bare Aluminum & Aluminum-Alloy Welding

Trends and Recent Changes to AWS Filler Metal Specifications Tuesday, October, 8, 2013 The Best Welding Location in the Nation The cast of characters filled the Toscana Party Center’s banquet room with welcomes, greetings of all sorts,

At one time or another you’ve probably browsed the contents of a filler metal specification sheet. Listed, of course, is the standard data—available wire or electrode diameters, product characteristics, features and benefits, operating parameters, and shielding gas requirements.

Typical Applications. Specifically designed for increased productivity and high deposition rates on challenging structural steel erection, heavy equipment repair, mining equipment, bucket repairs, storage tanks, pipe spooling, ship construction and site work applications.

aws fmc filler metal comparison charts More than 80 producers and marketers of filler metals have supplied trade names of thousands of products conforming to AWS filler metal classifications. Products are tabulated by filler metal classifications within the thirty individual specifications.

The specification contains testing procedures. and completely the required filler metal specification. and properties of weld metal from more than 30 classifications of nickel and nickel-allo The chemical compositions of nearly fifty nickel and nickel-alloy welding electrodes and rods are specified. and PA welding. The requirements include mechani The compositions specified for each

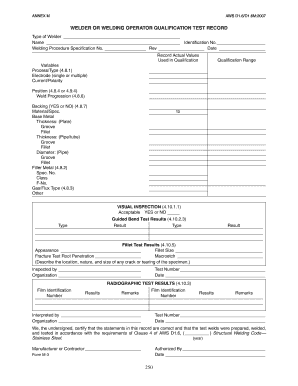

Figure G.3—Example of a Performance Qualification Test Record

Selecting Filler Metals Electrodes for Stress Relieved

specification compliance: aisi/aws a5.18 & asme sfa 5.18 er70s-2 APPLICATION: ER70S-2 is a triple deoxidized (Aluminum, Titanium, Zirconium) welding wire designed for welding over rust and mill scale.

Weld metal deposited by MONEL Filler Metal 60 has properties similar to those of MONEL alloy It has good strength and resists corrosion in many media, including sea water, salts, and reducing acids.

TABLE OF CONTENTS Appendices Page No. I. Welding Procedure Qualification Record (PQR) 1 II-A. Performance Qualification Test Record 2 II-B. Welder Performance Qualification Record (Example) 3

A5.01, Filler Metal Procurement Guidelines. 4 See Annex Section A4, Certification, for further information concern- ing certification and the testing called for to meet this requirement.

Welding filler metals. 2 Böhler Thyssen Schweisstechnik Deutschland GmbH – 09_2005 Böhler Thyssen Schweisstechnik Deutschland GmbH – 09_2005 3 List of contents List of contents SMAW covered electrodes Page (low and medium alloyed) Summary 7 for the welding of unalloyed steels for the welding of creep resistant steels for the welding of fine grained structural steels for the vertical down

This document, together with an AWS filler metal specification, is intended to describe a uniform method for providing those specific details needed for filler metal …

Filler metal product approvals The Fabricator

Filler Metal Selection SCCPSS

ers provide to the AWS regarding their filler metals. Both the literature on filler metal specifications and filler metal comparisons may be obtained directly from the AWS. The AWS classification system is for minimum requirements within a grouping. Filler metals manu-factured within a grouping may vary but still be clas-sified under that grouping’s classification. A manufacturer may add

83821 Copper Technical Brochure Washington Alloy Co.

AWS FMC FILLER METAL COMPARISON CHARTS webstore.ansi.org

AMERICAN WELDING SOCIETY WELDING INSPECTOR

– AWS A5.8/A5.8M 2011 SPECIFICATION FOR FILLER METAL

AWS A5.9.pdf PDF Free Download – edoc.site

AWS Specifications for Filler Material Welding Steel

A5 Committee on Filler Metals and Allied Materials

fm718 Daiko welding

AMERICAN WELDING SOCIETY WELDING INSPECTOR

A1.4 In some cases, the composition of bare filler metal classified in this specification may differ from that of core wire used for the corresponding classification of covered electrodes classified in AWS A5.4, Specification for Stainless Steel Electrodes for Shielded Metal Arc Welding. Caution, therefore, should be exercised regarding the use of core wire from a covered electrode as bare

AWS A5.8M/A5.8:2011-AMD1, Specification for Filler Metals for Brazing and Braze Welding (errata issued for Table 4) AWS A5.9/A5.9M:2017, Welding Consumables – Wire Electrodes, Strip Electrodes, Wires, and Rods for Arc Welding of Stainless and Heat Resisting Steels – Classification

filler metal: Specification ASTM B 32 containing less than 0.2% lead (Pb) AWS Classification 300 Form 0.125″ wire Method of Application Manual face feed

filler metal in AWS specifications and for consumable inserts in the Military Specification. 5 See A3 (in Annex A) for further information concerning acceptance and testing of material shipped, and AWS A5.01. 5. Certification By affixing the AWS specification and classification designations to the packaging, or the classification to the product, the manufacturer certifi es that the product

The Forms in through A5 are suggested forms intended to serve as a check list for detailing filler metal requirements for procurement. and. Inc. and packaging for filler metals are specified in the filler metal specification and are not intended to be duplicated or modified in this specification. as the filler metal specification requires).) Al. and the supplemental designator is H4R. is the

The Forms in through A5 are suggested forms intended to serve as a check list for detailing filler metal requirements for procurement. and. Inc. and packaging for filler metals are specified in the filler metal specification and are not intended to be duplicated or modified in this specification. as the filler metal specification requires).) Al. and the supplemental designator is H4R. is the

AWS A5.18 Specification For Carbon Steel Filler Metals For